‘Snake Oil’ or ‘Viper Lipid'? How to Get the Most Out of Your Biostimulant

Biostimulants have much variation in the types of products that fit this group of crop inputs as well as variability within their respective categories. These differences induce many challenges in consistency of product performance and thus skepticism to the class of inputs as a whole. With so many products available on the market, it is challenging to know if these products were developed with adequate science and research or tossed together quickly to take advantage of the momentum this sector currently has. In the latter case, these products are often referred to as “snake oil”; while in the former case, the products could be referred to as “viper lipid” with a place to increase yield or return on investment. Only with a proper understanding of how a product works can a producer then properly place and use it to optimize crop performance, and as importantly, know when not to use it. Earn 1 CEU in Nutrient Management by reading this article and taking the quiz.

Biostimulants and biofertilizers and biologicals, oh my! It seems a new technology appears at the doorstep each day with the claim to be one of these new specialty products. While many of these products come from start‐up companies, the increasing acquisition of these businesses by the larger industry corporations is giving this input sector some traction. With so many products available on the market, it is challenging to know if these products were developed with adequate science and research or tossed together quickly to take advantage of the momentum this sector currently has. In the latter case, these products are often referred to as “snake oil”; while in the former case, the products could be referred to as “viper lipid” with a place to increase yield or return on investment. If one has interest to try one of these products on the farm, the first step is to identify whether you have a need for a biostimulant on your operation and then ensure the product you select is the right tool for the job.

The 2018 farm bill was the first legislation in the U.S. to provide a framework to biostimulants, describing them this way: “A ‘plant biostimulant’ is considered a substance or micro‐organism that, when applied to seeds, plants, or the rhizosphere, stimulates natural processes to enhance or benefit nutrient uptake, nutrient efficiency, tolerance to abiotic stress, or crop quality and yield.” While this proposed description is currently undergoing revision, the underlying principles of nutrient cycling and tolerance to abiotic stress are what separate these compounds from plant growth regulators or biopesticides.

Although biostimulants can be considered the “non‐living” category of the biological market, it is important to note that many of the products in this category were derived from living microbes or other biological sources such as seaweed or algae. Often the active ingredient is a metabolite derived from a microbial fermentation process, such as concentrated amino acids, sugars, or enzymes. When applied foliarly, these types of compounds often induce plant‐signaling responses to mitigate abiotic stresses such as drought. Conversely, when soil‐applied, those metabolites stimulate microbial activity by providing biological building blocks for growth, which is analogous to a vitamin or health supplement that we may take. While there are many different products on the market, a majority of them can fit into the following five groups: (1) amino acids/protein hydrolysates, (2) sugars, (3) marine extracts/alginates, (4) humic/fulvic acids, and (5) concentrated enzymes.

Amino Acids/Protein Hydrolysates, Sugars, and Marine Extracts/Alginates

The first three categories are often targeted as foliar applications to help crops tolerate abiotic stresses such as extreme temperatures or drought. Amino acids are the building blocks of proteins, and at a basic level could be utilized by the plant for direct crop growth. However, plants also use amino acids as signaling compounds to upregulate gene function and/or ion transport and chelation. Proline and a derivative of glycine, glycine betaine, are known to increase in concentration as a plant responds to drought stress, and these two compounds are commonly found as the active ingredient in biostimulant products. In a similar manner, sugar monosaccharides in specific concentrations can induce a stimulatory response in the upregulation of genes responsible for plant defense against abiotic and biotic stress. Although plants will naturally vary their sugar and amino acid concentrations in response to these stressors, the application of a foliar biostimulant may allow producers to proactively induce these plant defenses and minimize negative impacts (most often yield loss) associated with stressors.

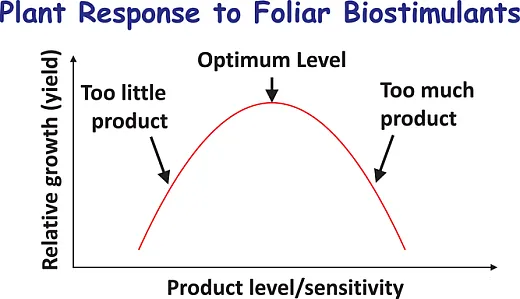

While the growing crop does not have access to the 10‐day forecast coming through the local news station, if one knows a drought is on the way or a southern hurricane is likely to be carrying pathogen spores north, then these products can be applied ahead of the stress. This helps the plant to have a defense already in place as opposed to fighting such a stressor on its own in a reactive manner. The challenge is the exact rate of amino acid or sugar needed to induce a positive response at just the right time is difficult to determine as it will vary based on the crop being grown, the stage of that crop, and current environmental conditions driving natural metabolite levels already present in the tissues. This is the Goldilocks Principle where there is an optimum rate to produce the desired outcome, but the use of too little or too much may overstimulate the crop, causing a yield penalty (Figure 1). In our own research, this was demonstrated using a foliar sugar in two separate years (Table 1).

After the results of the 2019 season, it seemed that foliar sugars would be a great success, but in 2021, the opposite results demonstrate the Goldilocks Principle. Conditions in 2019 interacted in a manner where the optimum rate was supplied, but in 2021, a differing optimum rate, or none at all, was needed. In this research, the crop was planted the first week of June in 2019 with applications applied on June 29, just days before the month of July started with higher‐than‐average temperatures. Conversely, in 2021, the crop was planted May 1, and seasonal temperatures at and soon after the V5 application were below normal, resulting in no heat stress. In 2021, the crop was told to build a defense for a stressor that never came, changing resource allocation in a way that detracted from a potential yield advantage. This is important to note as sometimes the optimum rate might be zero where conditions in the field do not necessitate the use of a product in that season. This means that shelf life of a biostimulant product should be considered if there may be circumstances where it is best to save the product for the following season.

While many of these products are targeted as foliar applications, the use of amino acids, sugars, proteins, and other plant metabolites found in alginate extracts also provides building blocks to stimulate microbial activity when supplied through the soil. This approach serves to stimulate the native microbes of a grower's field. A perfectly logical question might then be, “Why buy a product of living microbes if I can stimulate those same microbes already in my soil?” The answer comes down to management considerations. Those building blocks from the amino acid, sugar, and alginate categories will be used up quickly, inducing a short stimulation period for the native microbiome. While that may be enough to influence the crop's yield potential, the use of biostimulant products is a one‐time impact. Conversely, applying a concentrated microbial inoculant supplements the native microbes to provide continual nutrient cycling at higher levels than the native populations. The next steps in optimizing biological use may be to apply the beneficial microbes with biostimulants for a synergistic response.

Humic and Fulvic Acids

The fourth category mentioned above are the humic and fulvic acids, which have a more direct role in nutrient availability. Derived from mineral (leonardite or lignite) or organic sources, they are composed of carbon ring structures and carboxylic acid groups. When applied to soils, the aromatic ring structures can mimic plant hormones and stimulate root growth, providing better root‐to‐soil contact for nutrient interception. Additionally, the carboxylic acid groups are negatively charged, providing the ability to chelate soil cations like Ca and Al. Chelation of cations prevents them from binding to P, acting to improve fertilizer P availability just as P‐solubilizing microorganisms act through secretion of organic acids. Lastly, the carbon in these compounds can slowly be metabolized by soil microorganisms for their stimulation to cycle nutrients.

This biostimulant category has some of the widest range in product options to growers from a handling and input perspective. The amino acids, sugars, and marine extracts are almost always supplied as a liquid formulation at rates less than a gallon per acre, and some humic and fulvic acid blends fit this application approach. Conversely, some granular humic acids are labeled at use rates from 25 to 300 lb/ac, similar to the use rates of other soil amendments like lime that are applied every few years. One must decide what in their operation they wish to change or improve upon and then select the right management practice or product to fill that need.

While a yield response is often the first variable a producer considers when testing biostimulant products, there is also the potential to improve the quality of the grain. Three years of studies utilizing in‐furrow‐supplied humic or fulvic acids resulted in improved corn yield as well as overall protein production (Table 2). This fits the farm bill description where a biostimulant may improve grain quality. While today's markets do not have premiums for improved protein quality, this may change in the future, and while this case shows no yield difference of the humic and fulvic acids, there was a difference of these sources on grain protein quality.

Concentrated Enzymes

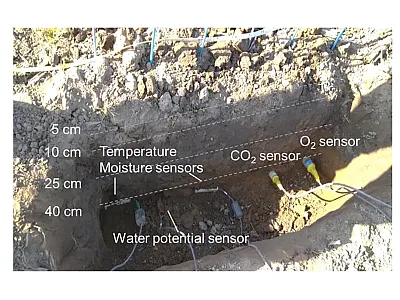

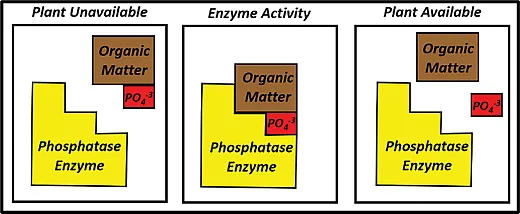

One of the newest categories of biostimulants, concentrated enzymes, provides for the direct mineralization of nutrients from soil organic matter and from the degradation of crop residues. Enzymes are the “machines” of biology, doing much of the work that microorganisms need to survive. Made up of proteins and extracted from microbial fermentation processes, enzymes come in different classes based upon the type of bond that they break. Enzymes currently used as nutrient enhancer products are phosphatases for the release of organic P (Figure 2), sulfatases that release organic S, and carbon enzymes like cellulases to help enhance residue decomposition and subsequent nutrient release. In these cases, enzymes are enhancing the release of organic nutrients and, as such, are not enhancing fertilizer efficiency directly. However, as excess fertilizer not used by the plant nor lost to environmental conditions can be immobilized into microbial biomass and over time become a part of the soil organic pool, enzymes can help to re‐release these fertilizer nutrients over time.

Conclusions

Biostimulants have much variation in the types of products that fit this group of crop inputs as well as variability within their respective categories. These differences induce many challenges in consistency of product performance and thus skepticism to the class of inputs as a whole. Only with a proper understanding of how a product works can a producer then properly place and use it to optimize crop performance, and as importantly, know when not to use it. As this sector continues to evolve, we expect that some “viper lipids” will separate from the “snake oils” and thus give producers another tool in the management box to improve crop yields. With extreme weather events becoming more frequent and less predictable, the potential of biostimulants is likely to grow, and with proper understanding and placement, we believe that they can benefit crop production.

DIG DEEPER

“Role of Biologicals in Enhancing Nutrient Efficiency in Corn and Soybean,” Crops & Soils magazine: https://doi.org/10.1002/crso.20263

“Plant Biostimulants: A Categorical Review, Their Implications for Row Crop Production, and Relation to Soil Health Indicators,” Agronomy: https://doi.org/10.3390/agronomy11071297

Self-Study CEU Quiz

Earn 1 CEU in Nutrient Management by taking the quiz. For your convenience, the quiz is printed below. The CEU can be purchased individually, or you can access as part of your Online Classroom Subscription.

- Biostimulants are currently regulated and grouped together with plant growth regulators and biopesticides.

- True.

- False.

- Which of the following mechanisms is NOT associated with biostimulant action in row crops?

- Release of soil nutrients from organic matter.

- Improvement of fertilizer availability.

- Direct application of a nutrient for crop utilization.

- Increased tolerance to abiotic stress.

- The use of foliar biostimulants that mitigate effects of abiotic stresses such as drought should be applied

- proactively, prior to the drought.

- reactively, during the drought.

- retroactively, after the drought.

- None of the above.

- According to the Goldilocks Principle, the same rate of a foliar biostimulant should be applied to the crop at any growth stage under all environmental conditions.

- True.

- False.

- The amino acids, sugars, and marine extract biostimulants are almost always supplied as a liquid formulation at rates of

- <2 gal/acre.

- 3–4 gal/acre.

- 4–6 gal/acre.

- 6+ gal/acre.

- The ability of humic and/or fulvic acids to chelate cations in the soil is largely associated with what functional group?

- Carboxylic acid.

- Ester bond.

- Disulfide bridge.

- Ketone.

- Three years of studies utilizing in-furrow-supplied humic or fulvic acids resulted in improved corn yield as well as overall protein production.

- True.

- False.

- What nutrient in soils is often unavailable for crop uptake as a result of insoluble complexes with soil cations?

- Potassium.

- Phosphorus.

- Nitrogen.

- Sulfur.

- The enzymatic release of nutrients from organic matter is often referred to as which process?

- Immobilization.

- Volatilization.

- Fixation.

- Mineralization.

- Enzymes in the soil can be produced by bacteria, fungi, and crop roots.

- True.

- False.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.