Sweet Success

How One Sugarcane Variety Transformed Louisiana’s Sugar Industry

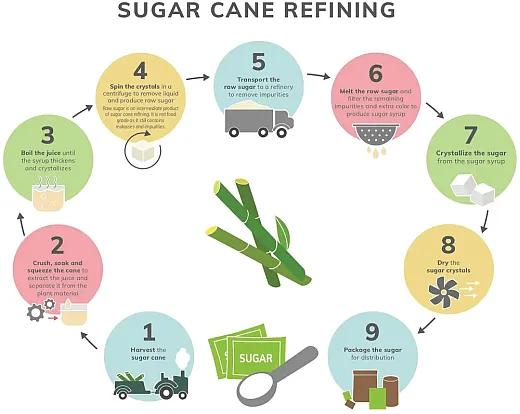

Sugarcane is a tropical tallgrass with stalks containing sucrose‐rich cane juice, which is harvested, extracted, and processed through a variety of methods to become the sugar we add to our coffee and bake in our chocolate chip cookies.

A new article in the Journal of Plant Registrations tells the story of the development of an important sugarcane variety in Louisiana, LCP 85–384, which was a cooperative effort among a land grant university, the federal government, and industry.

The development of this high‐performing variety, along with the machinery needed to handle it, led to sugar yield increases in the state of 22% and the rapid expansion of the industry.

When testing new sugarcane varieties in the field, sugarcane specialist Kenneth Gravois has a good rule of thumb for when you get to a good one. “It gets shady real quick,” he says. “It’s high population, not a lot of sunlight reaching the bottom of the row, it’s biomass,” adds Gravois, member of the American Society of Agronomy (ASA) and Crop Science Society of America (CSSA) who works at Louisiana State University (LSU) AgCenter’s Sugar Research Station in St. Gabriel, LA. “You know you’re onto something when it gets shady.”

Such was the case back in the 1980s when sugarcane breeders in Louisiana were testing a new variety called LCP 85–384, colloquially known as “384” for short. The product of a joint effort between the LSU AgCenter Sugar Research Station, the USDA‐ARS Sugarcane Research Unit, and the American Sugarcane League, 384 boosted sugar yield in the state by 22% and revolutionized the industry in the process.

“As a kid, my dad and grandfather grew 384 on the family farm,” recalls Brayden Blanchard, a Ph.D. student at LSU. Blanchard now works on crossings in the current breeding program at the Sugar Research Station. “Probably the first lesson learned once I got here was the impact that 384 was having,” he says. “As a new student, [there was] kind of this folklore about 384 in its prime and why it was so incredible at the time,” Blanchard says of the variety. “It really raised eyebrows… It stood out time and time again.”

Blanchard and colleagues recently published an article in the Journal of Plant Registrations (https://doi.org/10.1002/plr2.20370) about the history of 384, taking stock of its impact on sugarcane in Louisiana. “We felt like … decades past its release, it was finally time to give 384 its due,” he says.

“We distinctly remember 384 as a variety that stood out in early stages and on throughout its development,” reflects ASA member Herman Waguespack, research director for the American Sugar Cane League who worked on the later stages of the variety’s development. “It really did revolutionize the industry.”

A Quick History of Louisiana Sugarcane

Sugarcane, in the genus Saccharum, is a tropical tallgrass with stalks containing sucrose‐rich cane juice, which is harvested, extracted, and processed through a variety of methods to become the sugar we add to our coffee and bake in our chocolate chip cookies. A perennial crop, sugarcane is propagated through multiple “ratoons” that grow from a single planting after the aboveground stalk is harvested.

Jesuit priests first brought the plant to Louisiana in the mid‐eighteenth century, a time when the territory was still a part of colonial France. “It was introduced from various ports in the world,” says Freddie Martin, Professor Emeritus at LSU who was head of the breeding program that created 384. Most of these cultivars were variants of the species S. officinarum. “It was what they were calling the ‘noble varieties,’ the varieties that they found in Papua New Guinea and other parts of Asia,” Martin explains.

In 1795, the planter Étienne de Boré produced the first granulated sugar in Louisiana, boosting demand and quickly making way for sugarcane to supplant indigo as the colony’s most popular crop. With such a wide and open exchange of varieties came the introduction of many diseases, particularly Sugarcane mosaic virus (SMV), which nearly wiped out the industry in Louisiana and other parts of the world in the early 1900s. While growers were able to substitute in virus‐resistant cultivars from Java, Indonesia to save the industry from total implosion, “at that point there was realization amongst the growers that there needed to be improvement in the varieties,” Martin says.

The USDA established sugarcane breeding programs in Canal Point, FL and Houma, LA in 1919 and 1926, respectively, to address the challenges. The latter became home to an introgression breeding program in 1954 after SMV popped up again in an imported interspecific cultivar.

“They realized that to keep improving the varieties they had to constantly have integration from the wild‐material‐related genera,” Martin says of program’s founders. To do so, they began crossing several clones of the sugarcane wild type, S. spontaneum, that proved to be resistant to SMV with the existing inter‐specific hybrids. In 1926 LSU, USDA‐ARS, and the American Sugarcane League began collaborating and later established the basic breeding program that continues today with the same goal: to diversify the genetics of modern sugarcane cultivars.

“That’s an ongoing program to constantly bring in new genes, new sources of resistance to diseases and insects, along with improving the yield potential of the varieties,” Martin says. “It’s from that program that 384 came.”

Cold Tolerance and Visual Impact

In its early stages, the program also focused on incorporating traits like cold tolerance in addition to disease resistance into the populations. Though warmer overall than many other states in the U.S., Louisiana hosts a climate that can be challenging for tropics‐acclimated sugarcane. “If you pay attention to the weather in Louisiana, it could be very different from one year to the next,” Martin says. “It’s not uncommon to have a freeze towards the end of the harvest.” The cane can deteriorate quickly with a freeze, severely limiting the amount of sugar that can be extracted from it.

One cross done in the breeding program, made between male parent CP 77–407 and female parent CP 77–310 at the USDA‐ARS Sugarcane Field Station in Canal Point, FL in 1978, produced progeny that later became LCP 85–384. From there, breeders sent the seed to LSU. Researchers germinated it in a greenhouse and planted it at field stations where it underwent a series of stages of clonal propagation. At a later point, researchers took measures of sucrose content in the lab from juice extracted from the cultivar’s stalks. “Then they go through a stage of simple selection for cane quality, and then you’re visually looking at them for stalk number,” explains Scott Milligan, a plant breeder who worked closely on the development of 384.

From the time researchers planted 384 in the field, the variety’s potential was obvious. “Most varieties, the changes are hard to see or they’re very small. But this variety [had] a lot of stalks. It’s just very easy to see. Anybody can see the difference,” Milligan says. “I think the really high stalk numbers of 384 were visually impactful.”

In other words, “you didn’t need statistics when you found this variety,” is how LSU professor and sugar researcher Collins Kimbeng paraphrases the assessment. “You didn’t have to be a real expert on taking lots of lab measurements to tell that this was a high‐yielding variety, consistently,” says Kimbeng, a CSSA member.

In addition to visual and other assays of the variety’s biomass, researchers tested 384’s tolerance of Louisiana’s temperate climate. “You can have a rainy year, and it did well. A moderate drought, and it survived that easily,” Martin says.

They also tested for 384’s resistance to the troublesome SMV in greenhouse and field trials. By the 1990s, the bacterium Leifsonia xyli subsp. xyli, which causes ratoon stunting disease, was a new threat wreaking havoc on sugar globally. The LSU AgCenter later developed a tissue‐blot immunoassay screening method for the infection that they used to further test 384.

Ratoon ability was also an important trait in the variety’s testing. In leading the breeding effort, Martin emphasized economics of the crop in the variety’s evaluation. “I knew that in order to keep the industry going … the farmers had to make money,” he says. The number one cost, he found, was planting and the number of ratoons a grower could get out of each planting.

“One of the reasons 384 stood out is that it became very obvious early on that rather than getting three crops per plant, a farmer could get at least four if not more,” Martin says.

Here Comes the Combine

LCP 85–384’s registration appeared in the May 1994 issue of Crop Science (https://bit.ly/4bSzMIH). At the same time, the Louisiana sugarcane industry began adopting new harvesting technology. From the early 1940s onward, Louisiana had relied on soldier or whole‐stalk harvesters, which travel across sugarcane rows cutting stalks and dropping them on the ground. The stalks would then be picked up and placed into wagons for transport to the next processing steps.

This method had some limitations. Higher‐yielding sugarcane varieties like 384 tend to lodge, and the soldier or whole‐stalk harvester can’t pick up fallen stalks. Before 384 came on the scene, a major focus of the basic breeding program was breeding for “harvestability,” or less brittle stalks. At this time, it was common knowledge “that these heavy‐yielding and lodged canes, they can’t be harvested, so we dropped varieties,” Milligan says.

A combine or chopper harvester, on the other hand, can pick up lodged stalks with relative ease. Once it gathers the stalks, the machine chops them into sections known as “billets,” which are transported up in an elevator and deposited in an adjacent wagon.

Early adoption of combine harvesters in Louisiana faced some false starts due to trouble moving the new machines through Louisiana’s muddy fields. Once the combines were outfitted with tracks that could contend with Louisiana’s wet harvest‐time conditions, “they could get the machines in the field, and these things could just harvest lodge cane to a much greater degree than these old whole stalk harvesters,” Gravois says.

Gravois reflects on this change in his own family. “I can remember riding on the whole‐stalk harvester on weekends or holidays with my brother,” he says. “They would wait to cut the worst‐lodged cane because they had help on the weekend to ride it.” In the mid‐1990s, his cousin got a combine harvester, and then his family soon followed suit. The new machinery “generated a lot of interest and skepticism and excitement at the same time,” he says.

“The yield potential, and of course that means the profit potential, for 384 was so obvious that they were motivated to make it work,” Milligan adds. “Harvest machinery is very expensive, and it was a wholesale change in the way it was harvested in Louisiana.”

Impact at Home and Abroad

Louisiana sugarcane growers now had a high‐performing variety and the machinery needed to handle it. Rapid expansion of the industry quickly followed. The combine harvester was so important, Gravois says, that those who didn’t make the investment in combines “kind of got left behind because the variety offered the yield advantage that everybody talked about.”

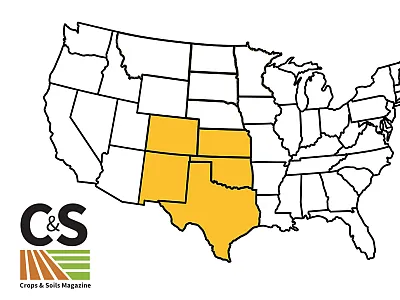

The cold tolerance of the variety allowed growers to start planting 384 in new parts of the state. “This particular variety lasted longer after a freeze. We could take a chance on sugarcane further north and west,” Waguespack says.

“In the last 10 to 12 years, our industry has expanded by 140,000 acres,” Gravois adds. What allowed for that recent expansion? For one, a consistent price of sugar that is more stable compared with grain crops. “But secondly, good genetics because most of that expansion has been further north into the cold‐prone areas.”

When the variety was released in 1993, 390,000 acres of sugarcane were in production in Louisiana, with each acre averaging around 5,000 lb of sugar. The state had 20 sugarcane mills and about 800 farms at that time, according to Waguespack. Today, 30 years later, there are 532,000 acres in production, and the average sugar per acre in 2023 was about 7,000–8,000 lb. The state has halved its number of mills to 11 and has halved its number of farmers as well. That means “we have larger farms and larger mills,” Waguespack says. “We were doing less than 1 million total tons of sugar, and now we’re doing right at 2 million,” he explains. “We doubled the amount of sugar produced in Louisiana in that 30‐year period of time.”

Not only did the industry double its yield, but it lengthened the crop cycle. In 1970, Gravois estimates about 40% of the industry’s sugarcane crop was in plantcane, 40% was in its first ratoon, and 20% was in its second ratoon. Today, there are nearly equal classes of sugarcane grown as plantcane, first ratoon, second ratoon, and third and older ratoon crops. “To increase the annual yields and lengthen out the crop cycle is, when you look back, really astounding,” he says. Other metrics of success include the completion of large capital projects to expand mills and work done among stakeholders in the state to decrease the quantity of pesticides applied through the improvements made in insect disease resistance.

And 384 has made its mark outside of Louisiana. It’s currently the industry‐leading sugarcane variety in Argentina, where it meets similar environmental needs and has also served as the parent of a newly released cultivar. But in other sugar‐growing states in the U.S., 384 has been less successful, for example in Florida’s more typical year‐round tropical climate. “I tried using 384 in Florida, and it just wasn’t adapted. It didn’t do that well there,” Milligan says.

To Blanchard, that anecdote illustrates what makes 384 powerful. “It’s the most perfect story of fitting a cultivar and all its characteristics to the needs of a very specific industry that has these specific challenges,” he says.

Making Advances Through Cooperation

In quantifying 384’s impact, Blanchard delineated two important lessons learned in the creation, release, and use of the variety. One is the value of identifying good genotypes as early as possible in breeding. “It’s so easy to dismiss a variety, and when you’re dealing with literally tens of thousands of genotypes, it’s so easy to drop the wrong ones,” he says.

Another lesson was learned the hard way in 2004. By then, LCP 85–384 made up 91% of all acreage in the industry. “As a breeder, as a geneticist, that’s a nightmare. That’s overreliance on one package of genetics,” Blanchard says. This monoculture scenario led to adaptations made in brown rust (Puccinia melanocephala), which 384 had initially been resistant to, and growers suffered serious losses from the disease. Today, the researchers are assessing how much of the breeding program’s germplasm is highly related to LCP 85–384. “In breeding, we always talk about standing on the shoulders of giants,” Blanchard says. Two of the current industry‐leading varieties, HoCP 96–540 and L 01–299, are direct progeny of 384.

In all, the researchers say that LCP 85‐384 is truly a product of its environment—of the climate and needs of Louisiana, but also of its breeding program. Without the cooperative agreement between a land grant university, federal government, and industry, such advances wouldn’t be possible.

“384 is an outstanding variety, but I always looked at it as the product of a system … without that system, I don’t think you would have had this variety—or any variety,” Martin says.

Gravois agrees. “Undoubtedly, coming together and working toward a single goal is, to me, the real success. I don’t think any one group out of these three could have done it on their own,” he says.

Dig Deeper

Blanchard, B. A., Taylor, Z. A., Rivette, M. G., Kimbeng, C. A., & Gravois, K. A. (2024). The release of ‘LCP 85–384’ and its contribution to the Louisiana sugar industry. Journal of

Plant Registrations, 18, 221–240. https://doi.org/10.1002/plr2.20370

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.