Thinking Big About Recycling

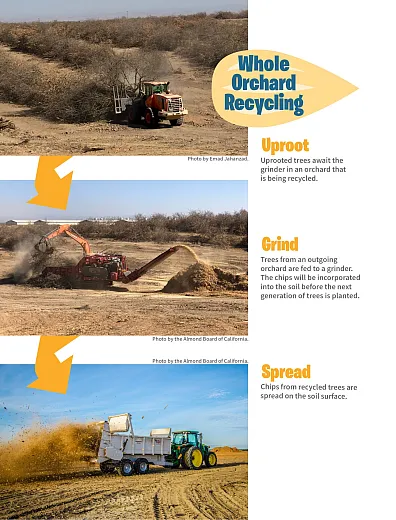

California almond growers, who replace their orchards once every few decades, used to have two options for disposing of aging trees: After uprooting them, they could either burn them on site, or grind them and sell the biomass to cogeneration plants. As new environmental policies take hold in the state, those options are being phased out. Filling the gap is the more environmentally friendly practice of whole-orchard recycling, which though costlier in the short term, offers considerable long-term agronomic benefits. Scientists hope their deepening understanding of these advantages will convince more farmers to make the switch.

We all know recycling is a good thing, and most of us try to do our part. This time of year, with Global Recycling Day (18 March) and Earth Day (22 April) upon us, we may be especially careful to toss used cans, papers, and bottles in the proper bins. But in California, the birthplace of many a green innovation, almond growers are taking the practice to an entirely different level: Recycling entire orchards.

Almond trees don’t produce forever. After 20 to 25 years, as yields drop off, growers in the state’s 7,600 almond farms know it’s time for a reboot. In the past, this typically meant one of two things: burning the trees and then spreading the ash back on the land; or grinding them and selling the chips to cogeneration plants.

While many of the state’s 1.6 million acres of almonds are still managed that way, an alternative has gained traction over the past decade: Grind up aging trees on site and then incorporate the chips right back into the soil. Studies have shown that whole-orchard recycling (WOR) provides enough long-term benefits for the soil and trees to make the once-in-a-generation investment well worth it.

“There's no practice that puts that much organic matter into the soil at any one time,” says Josette Lewis, chief scientific officer for the Almond Board of California (ABC). “No amount of composting does that in such a short period of time. It really has, as we've seen through the research, this really dramatic impact on soil quality.”

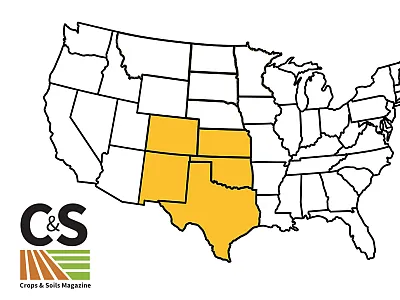

The more they study WOR, scientists say, the more pros for soil and trees they are discovering. But in addition to this enticing carrot, a powerful stick is prodding farmers toward recycling: state regulations aimed at improving air quality and promoting renewable energy. These powerful factors are driving a veritable WOR revolution: According to ABC estimates, almost half of the orchards removed in the past two years have been recycled. But, as we’ll explore in this story, many other factors are contributing to this shift, as well, including market pressures for sustainable farming, vocal industry support, financial incentives, compelling research, and the persistence of the inspired innovator who got the WOR ball rolling.

A Small Idea Gets Bigger ... and Bigger

In the late 1940s, a nurseryman named Leonard James acquired 70 acres in California’s Stanislaus County and began farming almonds. Over the years, the nearby city of Modesto sprawled ever closer to his orchards, eventually enveloping them. At the same time, concerns over air pollution grew in that booming part of the northern San Joaquin Valley, situated within 100 miles of San Francisco, Sacramento, San Jose, and Fresno. By the late 1990s, it became clear that the days of burning old trees to make way for new were numbered.

So, James’s family bought a small woodchipper and began chipping rather than burning prunings and then spread the mulch below their trees. Brent Holtz, James’s grandson and a doctoral student in plant pathology at the University of California–Berkeley, observed how well the trees thrived and soil texture improved.

By the turn of the century, Holtz, by then a farm adviser with the University of California’s Agriculture and Natural Resources division (UCANR), decided to go a step further. If recycled branches could benefit the trees, what about recycling an entire orchard? To test this idea, he ran his own experiment at the farm, planting 10 young trees in barrels filled with soil amended with the quantity of woodchips that, he estimated, would be generated by grinding a whole orchard and spreading it out on the land. As the saplings grew, he compared them to a second set of trees planted in unamended soils.

Over the years, he observed that the trees with woodchips not only stayed healthy, but also grew and produced more than the control trees. Underground, water infiltration, soil organic matter (SOM), and soil organic carbon all improved—encouraging news given the drought-prone climate and area soils naturally low in carbon and SOM. Holtz was eager to ramp up to a large-scale orchard trial.

In 2008, an experimental orchard finally became available at UCANR’s Kearney Agricultural Research and Extension Center. But there was a big problem: Where would Holtz get a machine powerful enough to grind up all those existing trees? As luck would have it, a massive rock crusher was spotted doing work near the Kearney Center one day, and Holtz pounced. If it could grind up rocks and roads, he figured, it could grind up whole trees. He arranged to rent the “Iron Wolf” the following day (paying the $4,000 fee out of his own pocket), designed a replicated experiment that night, and unleashed the 100,000-pound monster the next morning.

“I can't say I woke up one day and wanted to do a whole-orchard recycling trial,” recalls Holtz, now UCANR’s county director in San Joaquin County. “But I saw the benefit of chipping up prunings, and then the goals and the dreams just kept getting bigger and bigger.”

The Iron Wolf sucked in whole trees through its 6-inch titanium teeth and spat them back out in pieces, creating mountains of mulch. (The rock crusher turned out to be a bit overkill: Today excavators, working with horizontal grinders and front-end loaders, recycle orchards much faster.) About 30 tons of chips per acre were incorporated into the soil, and then new almond trees were planted exactly where their predecessors had stood. Holtz began gathering data.

In 2015, Holtz met Amélie Gaudin, an associate professor in the Department of Plant Sciences at the University of California–Davis, who signed on to the project, found funding, and brought in a postdoc, Emad Jahanzad. The researchers compiled data and compared the trees’ performance over a decade to nearby treatment plots where trees had been pushed and burned.

In results published in 2020, the team reported that WOR resulted in a slew of benefits. The soil in the recycled orchard had better SOM, soil carbon, water retention, and soil aggregation. The trees displayed less water stress and—of key importance to growers—better yields. “Over a 10-year period, there's almost 2,000 kernel pounds more in the grind treatment than the burn,” Holtz says. “At $2 or $3 a pound, that started to be an incentive alone for growers.”

But was it incentive enough for growers to overlook the $1,000-per-acre cost—much pricier than conventional orchard replacement? Not really. Although growers first heard about WOR’s agronomic benefits when Holtz wrote about it in Pacific Nut Producer in 2015, few farmers were willing to try. However, other forces were conspiring to steer producers toward the practice until it seemed just a matter of time before all of the state’s 140 million trees—80% of world production—would end up right back in the ground they came from, by way of a grinder’s jaw.

Environmental Pressures and Industry

Support As a new way to replace orchards gained a foothold, the two existing methods seemed destined for extinction.

In efforts to control pollution, California’s local air districts were issuing fewer burn permits to farmers. The San Joaquin Valley Air Pollution Control District, grappling with some of the nation’s worst air quality, is slated to phase out ag burning completely in 2025. And the state’s decision to move toward 100% carbon-free electricity by 2045 sounded the death knell for cogeneration plants, which stopped buying woodchips from farmers.

It was about that time that a very important player entered the picture, Holtz notes: the state’s Almond Board.

“That's when the Almond Board and industry really got interested because the industry needed an alternative,” Holtz says. “They couldn't burn in the field, and they couldn't burn in the cogeneration plant.”

A key tipping point, it seems, had been reached. The Almond Board of California began funding WOR research and spreading the word about its benefits. The practice became a linchpin of its sustainability plan, which includes a goal to achieve zero waste by 2025. Lewis says that between solving the woodchip problem, more water retention, and other agronomic perks, WOR is the industry’s future.

“There aren't that many practices that have such multiplier effects in terms of benefits sets,” she says.

One huge such effect is carbon sequestration. The practice, according to the Almond Board, could sequester an estimated 2.4 tons of carbon per acre. In addition to being a potential source of farmer income through the carbon market, WOR tells a compelling stewardship narrative that increasingly resonates with food producers and consumers. With the right product, sustainability sells.

“There are companies that are trying to incentivize and encourage growers to use whole-orchard recycling—food companies or almond processor companies that sell into the marketplace—in part because of that powerful storytelling,” Lewis explains.

Consumers are more likely to respond to a narrative about the delicious drupes than one about anonymous legumes. “It's not like corn or soybeans, which are often fed to animals or highly processed into a food product,” Lewis points out. “An almond is something that people really recognize directly.”

While heart-warming tales about almonds may not motivate growers to switch to WOR, another time-honored strategy is proving effective: money. Several agencies are helping with costs for producers, including the San Joaquin Valley Air District, the California Department of Food and Agriculture’s (CDFA) Healthy Soils Program, and USDA-NRCS. While many farmers remain reticent, others are converting. In the San Joaquin Valley alone, more than 500 growers have recycled 26,000- plus acres, according to the Almond Board. Businesses have sprouted up to respond to growers’ demand for large-scale grinding. Walnuts and other orchard crops have begun adopting the practice, and last year, a trial launched in Australia, the world’s second largest almond producer.

Gaudin credits Holtz for much of this success, thanks to his passion, teamwork skills, and connection with growers. “Brent has been a true visionary for researching and developing WOR practices at scale,” she says, recalling the team’s struggle to find funding early in the project. “He was 10 years ahead of his time, and it took a lot of perseverance and courage to move forward.”

For many farmers, the clock is ticking: Those slated to replant their orchards soon may not get another chance to try WOR since turnover happens only once a generation. “If you get the opportunity to time it just right, you'll reap those benefits for many years to come,” Lewis says.

Still, there’s one big problem with dumping tons of carbon into the soil at one fell swoop: Nitrogen immobilization. The most recent publication coming out of the WOR research team tackles it head on.

Managing Nitrogen in Recycled Orchards

A healthy soil is a well-balanced soil. You want enough carbon and nitrogen to make both crops and soil microbes happy. Typically, that means a C to N ratio of no more than 20:1 to 24:1, explains Jahanzad, who went on to be a senior environmental scientist with CDFA. But WOR throws that balance way out of whack.

“When you return 40, 50, 60, 70 tons of carbon per acre to the soil, it's a lot of carbon,” Jahanzad says. “When you add that much carbon to the soil, there is a risk to immobilize nitrogen temporarily.”

As Jahanzad explains, the sudden carbon deluge—the C:N ratio catapults to 140:1—is a windfall for soil microbes, whose populations surge. The ensuing microbial multitudes quickly deplete the initial N influx, leaving little for the N-hungry almond saplings. Unaddressed, the imbalance can lead to stunted trees.

This article is protected by copyright. All rights reserved. That would appear a significant strike against WOR. However, ongoing research led by Holtz and UCANR colleague Mae Culumber shows those deficits last just one year and can be managed. Although the researchers initially recommended that growers increase nitrogen fertilization from 3 oz per tree to 5 that first year, they now believe early fertilization and better root zone placement may mitigate the need for additional nitrogen, Holtz says. By Year 2, the cycle appears to catch up with itself with enough microbes dying to release sufficient N back to the soil to replenish N supplies for saplings.

“A major part of biologically active nitrogen comes from the microbial biomass,” explains Jahanzad, a co-author on these findings. “When they start decomposing organic matter in the soil, they release that nitrogen available to the plants.” The research, which informed new guidelines for WOR- practicing growers, are slated to be published later this year.

And what about nitrogen and water quality? The researchers tackled that, too.

Over the decades, due in part to inefficient fertilization and irrigation, nitrates have leached into California’s groundwater, raising health concerns. The WOR researchers reasoned that recycling would mitigate leaching.

“Since nitrate is mobile in the soil, wherever water goes, it takes nitrates with it,” Jahanzad explains. “If the water can be retained in the root zone, that means that nitrate can be retained the root zone too, meaning that it's not going to be lost through leaching.”

The team designed a column study to test their ideas. They compared soil gathered from a 10-year- old orchard managed by burning to a WOR orchard of the same vintage. They did the same with a pair of one-year-old recycled orchards.

To distinguish the fate of N applied in fertilizer from that of N already in the soil, they isotopically labeled it. After spreading the fertilizer and irrigating, they measured parameters related to nitrogen release, including microbial biomass, nitrogen, total nitrogen, and nitrate in the leachate.

In the one-year-old orchards, they found little difference in the leaching while, as expected, microbes immobilized part of the N from the fertilizer. But samples from the 10-year-old WOC- managed orchard told a different story: As the team recently reported in the Journal of Environmental Quality (https://doi.org/10.1002/jeq2.20385), leaching was 52% lower in the recycled treatment than in the burn-managed orchard, and immobilization was no longer an issue.

“That's an enormous difference,” Lewis says. That retention power is especially important given state mandates that farmers report nitrogen application and uptake and that they lower nitrogen use. “To help meet another regulatory requirement here in the state,” Lewis adds, “that will be of significant value.”

The Long-Term Dividends of Recycling

Holtz is still working to demonstrate WOR’s value. He continues to monitor the trees in his at-home barrel trial and reports that SOM and soil carbon remain significantly greater 20 years later.

This article is protected by copyright. All rights reserved. The escalating effects of climate change will only multiply WOR’s benefits. Water retention will be even more valuable as temperatures rise and droughts worsen: Jahanzad says farmers who practice WOR tell him they need to irrigate much less.

Holtz is excited about the team’s latest trial at the Kearney Center where they are fertilizing trees with three different N rates: the recommended rate, 20% less than that rate, and 40% less. “We have two preliminary harvests, and right now we haven’t seen any difference between our low treatment, our medium, and high treatment,” Holtz reports. “So, we hope to show that with whole- orchard recycling we can use less nitrogen in the long term.”

Holtz is also experimenting with adding even more chips on WOR orchards. “I think our soils can handle more organic matter than we're giving it once every 30 years in this process,” he says. “I'm hoping that this annual application of woodchips will be like growing a cover crop, helping with infiltration and fertility.” He’s also looking forward to re-recycling the orchard the team recycled at Kearney back in 2008, which would be the first time an orchard has been recycled twice.

That's the kind of bold, creative, and positive thinking agronomy needs these days, Gaudin says. “Disruptive and innovative ideas like this have to be celebrated,” she says, “and Brent’s efforts with this practice in particular will have a lasting impact on California agriculture and our ability to meet our sustainability and resilience goals.”

DIG DEEPER

Read the original article, “Effects of Whole-Orchard Recycling on Nitrate Leaching Potential in Almond Production Systems,” in the Journal of Environmental Quality: https://doi.org/10.1002/jeq2.20385.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.