How does flue-cured tobacco respond to the herbicide glufosinate?

Flue-cured tobacco is the most valuable crop produced in North Carolina. It is susceptible to glufosinate, yet it is commonly grown in close proximity to crops that are tolerant to the herbicide.

Although field trials found simulated glufosinate drift onto flue-cured tobacco significantly reduced per-acre yields, it did not affect the crop’s per-acre value.

Nevertheless, growers and applicators should strive to minimize drift, which starts with reading, understanding, and following product labels.

Flue-cured tobacco is the most valuable crop produced in North Carolina. It is susceptible to glufosinate, yet it is commonly grown in close proximity to crops that are tolerant to the herbicide. Although field trials found simulated glufosinate drift onto flue-cured tobacco significantly reduced per-acre yields, it did not affect the crop’s per-acre value.

Matthew Vann, a member of all three Societies and a North Carolina State University (NCSU) assistant professor and tobacco Extension specialist, led the research, which was published in Crop, Forage & Turfgrass Management (https://doi.org/10.1002/cft2.20141). He says he suspects the plants compensated later in the growing season, putting on more of the higher-value top leaves. Nevertheless, he says growers and applicators should strive to minimize drift, which starts with reading, understanding, and following product labels.

The trials also served as a model for subsequent simulated drift research when herbicides, such 2,4-D choline and dicamba, were commercialized for use on herbicide-tolerant cotton and soybeans. This summer, Vann plans to conduct tobacco field trials into simulated drift of HPPD-inhibiting herbicides recently registered for use on HPPD-tolerant soybean varieties. A number of companies also plan to launch HPPD-tolerant cotton varieties and corn hybrids later this decade.

Importance of Tobacco

Conducted in 2009 and 2010, the glufosinate drift trials were in response to increasing weed resistance to glyphosate and growers turning to crops with the Liberty Link trait, Vann says.

“We just saw a lot of new products coming out that coincided with what was emerging with glyphosate, primarily in cotton and beans,” he says.

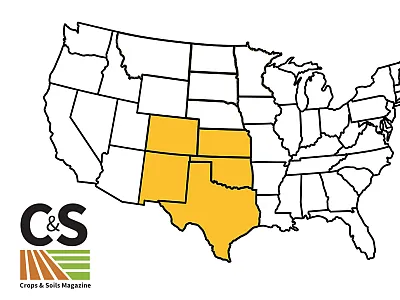

North Carolina growers used glufosinate on about 65% of the state’s row-crop acres in 2020, according to a survey by NCSU research associate Eric Jones. Flue-cured tobacco accounted for 4.3% of North Carolina’s farm cash receipts in 2020.

The most widely grown tobacco type in the United States, flue-cured is cured in heated barns. Burley, the second most widely grown tobacco, is slightly taller in stature and is air-cured. And dark fire-cured tobacco is cured using fire in barns.

Over the past decade, North Carolina growers also have diversified, so it’s not unusual to find glufosinate-tolerant crops right across the turn-row from tobacco, Vann says.

Even with the advent of auxin-resistant crops, he says only seven cases of off-target herbicide movement involving tobacco were reported to the North Carolina Department of Agriculture and Consumer Services in 2017. Granted, those were the ones that were reported, and he suspected a number of additional events went unreported.

“From a practical standpoint, we’ve done a really good job of conducting grower training to try to mitigate these problems and reduce issues as a whole,” Vann says, citing the work of his NCSU Weed Science Extension colleagues. “We’ve not really had the number of problems reported in other states, and I think it’s because more of our growers are so diversified that they’re not comfortable using some of these technologies.”

Neither University of Tennessee (UT) Extension tobacco specialist Mitchell Richmond nor University of Kentucky Extension tobacco specialist Andy Bailey have been on farm calls that involved glufosinate drift onto tobacco. Both say the most common tobacco drift complaint was off-target movement of dicamba. And Richmond says he visited one farm in 2021 with paraquat drift onto tobacco.

Simulating Drift

Glufosinate has very low volatility, so crop damage occurs from physical spray drift or improper sprayer clean-out, according to Vann.

The drift trials were conducted over two years and in two locations. After about five to six weeks in the field when the plants were about 24 inches tall and had about 10 to 12 expanded leaves, the researchers subjected them to sublethal glufosinate rates (½, ¼, ⅛, 1/16, and 1/32 of the full rate) designed to mimic drift. The application timing coincided with when growers would traditionally be making applications to glufosinate-tolerant row crops, Vann says.

Seeing Yellow

The researchers returned one and two weeks after application to visually rate the treatments. Injury was easy to assess because leaves turned a bright yellow. Vann says he knew of no other sublethal herbicide rate or nutrient deficiency that produces that vivid a yellow. Sulfur deficiency, for example, produces slight leaf yellowing fairly uniformly from the top of the plant to the bottom. Potassium deficiency, on the other hand, tends to appear as yellowing of the leaf tip while veins remain greener.

Tobacco also is very sensitive to growth regulator herbicides, such as dicamba. Symptoms of sublethal rates include cupping, ruffled edges, and exaggerated tips on leaves.

“We were mostly looking at what color the leaves were,” Vann says. “With glufosinate, the biggest indicator in tobacco really seems to be at sublethal rates the tissue is a bright yellow color. At two weeks after treatment, particularly with the higher-concentration half-rate exposure, we did have a little bit of necrosis on some leaf tips. But we didn’t have any real dieback.”

One week after treatment, visual injury ranged from 15 to 83% compared with the untreated check. Among the treatments, visual injury nearly doubled as the sublethal rates increased from 1/32 of full rate to 1/16 of full rate. This also was seen between 1/16 and ⅛ of the full rate. Although injury increased between the ¼ and ½ rates, it wasn’t as pronounced.

The researchers saw similar trends when they rated the plots two weeks after treatment, with visual injury ranging from 10 to 83% compared with the untreated check.

About two weeks after the second rating, the plants had greened up. “We treated the plant early enough that it still had a lot of growing to do,” Vann says. “Because this was a contact material and not a systemic, there was additional plant growth to compensate.”

Vann says he wasn’t surprised by the results because glufosinate rapidly degrades after application and the plant quickly metabolizes it. He believes that burley tobacco would have similar responses to sublethal rates of glufosinate.

Post-Harvest Evaluation

At harvest, the researchers collected leaves from four stalk position groups—lugs, cutters, leaf, and tips—on each plant. The lowest leaves, called lugs, typically have the least value whereas the top leaves, known as tips, are the most valuable.

The leaves were cured, weighed, and assigned a USDA visual quality grade. The cured leaf economic value was determined using a combination of leaf yield and quality.

Cured leaf yield declined as the sublethal glufosinate rate increased. The highest yield—2,789 lb/ac—was in the untreated check. Yield decreased about 47 lb/ac for every 0.01 lb/ac of active ingredient of glufosinate.

That said, the 0.27 lb/ac active ingredient rate resulted in the lowest cured leaf yield of 1,529 lb/ac or about 45% less than the untreated check.

Surprisingly, Vann says that the cured leaf visual quality and overall per-acre value were not affected by glufosinate exposure.

“We did see a (yield) decline, but I really believe where we had some leaves that really got a lot of the material, they ended up falling off of the plant,” he says. “I think because you still had the ability for the plant to compensate, we did have some plant growth from a quality stand point that was able to compensate for it.”

In 2009, the researchers also collected cured leaves to assay for glufosinate residue. They found none. The following year, they sampled green leaves and again found no measurable glufosinate residue levels.

Unlike other crops that may see a 5- to 10-bu yield reduction after a drift event, the entire tobacco crop or a large portion can be at risk, according to UT’s Richmond, a member of ASA, CSSA, and SSSA. Leaf buyers consider any tobacco exhibiting injury symptoms from a non-registered pesticide—even without detectable residues—unmarketable, and it must be destroyed, he says.

This can amount to a large financial loss since the producers grow the crop under contract. If it were dark fire-cured, for example, estimated gross revenue for 2022 is slightly more than $9,000/ac, Richmond says, citing UT’s production budgets.

“That means that if the tobacco producer loses 5 acres due to drift, then someone could owe that producer up to $45,000, depending on the timing,” he says. “One case last year resulted in 13 acres of burley being condemned.”

Annual Application Reminders

To minimize drift issues, Vann and Richmond emphasize reading and following the label and ensuring that sprayers are well cleaned and calibrated. These practices should be standard regardless of the crop. By and large, they say tobacco producers are knowledgeable about how to minimize drift.

Richmond also encourages producers to select fields with a reduced risk of potential drift. In other words, avoid planting tobacco in the middle of a soybean field. In addition, he reminds them to think about the previous year’s crop and the potential for carryover from a soil-applied residual herbicide.

Where the larger learning curve occurs is with non-tobacco growers, who may not be as aware of the crop’s sensitivity to herbicides, its high per-acre value, and its potential to be rejected with suspected herbicide damage, Richmond says.

HPPD Drift Studies This Season

This season, Vann says he plans to conduct similar tobacco drift simulation trials using varying sublethal rates of an HPPD herbicide. He also will include two application timings: an early- to mid-season one similar to glufosinate timing and one later in the season to simulate a worse-case scenario.

The later application also will likely mean more of the higher-value top leaves are exposed and the plant won’t have as long to compensate for possible leaf loss before harvest.

Dig deeper

View the original article, “Flue-Cured Tobacco Response to Sublethal Rates of Glufosinate,” in Crop, Forage & Turfgrass Management: https://doi.org/10.1002/cft2.20141

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.