How to optimize fungicide application for Fusarium head blight management

Applying fungicide to manage Fusarium head blight (FHB) in small grains is a complex task that goes far beyond just spraying. This article discusses selection of fungicides and nozzles and breaks down how droplet size, water volume, boom height, and sprayer speed affect application efficacy. Ultimately, integrated strategies—from variety selection to real-time disease forecasting—are key to management. Earn 0.5 CEUs in Integrated Pest Management by reading the article and taking the quiz.

Applying fungicide to an upright small grain head to manage Fusarium head blight (FHB) while going 12 mph or more can be a challenge, to say the least.

Using newer asymmetrically angled dual-spray nozzles that target both the front and back of grain heads typically improves coverage compared with single flat-fan nozzles, says Andrew Friskop, North Dakota State University (NDSU) Extension cereal pathologist. Lower boom height and course droplet sizes, particularly at higher speeds or during windy conditions, enhance the chances the fungicide will not dissipate before it hits the grain head. Using water volumes of at least 10 gal/ac—and preferably more—also improves grain head coverage.

Even so, he says application techniques are just part of an integrated management approach to FHB with proper application timing and fungicide choice being the most important.

In addition, disease-forecasting models can help determine disease risk and whether a fungicide is needed. Planting moderately resistant varieties, rotating crops, and residue management also are part of the multi-pronged management strategy.

“It’s a disease that truly would be a poster child for integrated management, starting with using a variety that has good resistance so you’re starting ahead of the eight ball,” Friskop says about FHB, also known as head scab.

Concerns surrounding Fusarium head blight

The reason for concern is the disease’s one–two punch. Fusarium head blight is caused predominately by Fusarium graminearum and to a much lesser extent, related Fusarium species. Like many other fungi, Fusarium flourishes during cool, moist weather.

The fungi infect wheat and barley from flowering to early grain fill and can reduce yields by up to 50% under severe conditions. In 2024, small-grain producers in the U.S. lost about 30.8 million bu to FHB, making it by far the leading head and kernel disease, according to Crop Protection Network estimates.

But more importantly, F. graminearum produces deoxynivalenol, also known as DON or vomitoxin. Even minute levels of the mycotoxin can result in grain loads being downgraded or rejected due to its toxicity to animals and humans.

The Food and Drug Administration in 2010 published an industry guidance for DON of no more than 1 ppm in finished wheat products. For chickens and ruminating beef cattle four months and older, the threshold is 10 ppm with the caveat that not more than 50% of the diet be from grain products. For swine and other animals, it’s 5 ppm with the same caveat.

The European Union, on the other hand, further reduced its DON thresholds in 2024 to 1 ppm in unmilled wheat, barley, rye, and corn.

Fungicide choices

Six registered fungicides in two classes—Fungicide Resistance Action Committee (FRAC) Groups 3 and 7—have proven the most effective in trials. Group 3 includes DMIs or triazoles, which have historically been the go-to products for FHB. More recently, SDHIs, which belong to Group 7, have been registered for FHB management. Most manufacturers offer the two FRAC groups combined in a premix product rather than as stand-alone chemistries.

Pathologists like Friskop describe the fungicides’ performance as suppression instead of control.

“Right now, there are good fungicides and fair fungicides,” he says. “The good ones provide 55–60% suppression, not so much because the fungicides don't work on small grains. It's because of multiple heading dates, and that's one of the biggest hurdles.”

Experts warn against using any Group 11 fungicides—QoI or strobilurin—because they may actually increase DON levels in grain.

Determining optimum application timing can be difficult because of variations in heading and flowering within a field, Friskop says. In wheat, the most effective application window is when about 15 to 20% of the main stems are at early flowering (Feekes 10.5.1) and up to seven days afterward. Making an application on the latter side of the window is better than on the earlier side, he says.

When he first started at NDSU about 13 years ago, Friskop says the thought was the window lasted only one to two days after early flowering. But research has since shown that applying fungicides up seven days after still provides good disease suppression. In barley, the window is from full heading until seven days afterward.

Hitting the target

The application window isn't the only change over the past decade or so. Nozzle and sprayer technology also has evolved.

As part of updating NDSU head scab management recommendations in 2024, Friskop and Rob Prouix, NDSU Extension agriculture technology systems specialist, reviewed research from 18 publications. They included the summaries in the grower- and applicator-focused publication, Ground Application of Fungicides for Fusarium Head Blight Management.

DMI fungicides applied to grain heads are locally systemic, meaning they don’t move up and down the plant, he says. Even within the grain head, they don’t move enough to provide adequate protection from FHB. This makes coverage all the more important as the fungicides are designed as protectants.

Add to that the upright nature of grain heads that frequently move in the wind, and fungicide application becomes even more complex.

When he first started at NDSU, Friskop says FHB was becoming a concern, but fungicides weren’t widely used in small grains. Back then, the nozzle selection was limited to mostly conventional flat fans.

While they can deliver a significant amount of fungicide to the front of the grain head, they apply little to none to the back side. As a result, some producers put adapters on their booms to angle nozzles either forward or backward to improve coverage.

But it was time-consuming and often unwieldy to change over a spray boom. In the meantime, nozzle manufacturers began developing single units just for small grains that could produce dual-angled sprays.

Nozzle selection

Tim Stombaugh, an Extension professor in the University of Kentucky’s (UK) Department of Biosystems and Agricultural Engineering, was part of a research project that examined the effect of nozzle configuration and ground speed on FHB management in wheat. Joining him were UK Extension Plant Pathologist Carl Bradley and UK doctoral candidate Nathaniel White. Their work was published in a 2023 issue of Plant Health Progress.

The UK researchers found that dual-angled asymmetrical nozzles improved coverage on the back of simulated wheat heads crafted out of water-sensitive paper compared with single flat-fan nozzles. But when they looked at the effects of nozzle configuration and sprayer speed on FHB management in actual wheat plots, Stombaugh says the results were somewhat inconclusive and a bit surprising.

They found no statistically different relationships between coverage and yield, FHB, or DON reduction. While not statistically significant, the researchers did note that the top three values for FHB control were from nozzles that provided the best coverage on the back of simulated wheat heads.

“When it came down to efficacy, [nozzle configuration and sprayer speed] didn’t seem to be the big driving factors that we thought they would be,” Stombaugh says. “We didn’t see statistical differences like we expected and were left scratching our heads.

“A lot of it comes down to the application rate and timing. How you put it on is obviously important, but it’s one piece of a lot of pieces that have to come together to get the best results.”

At least in their trial, the researchers concluded that nozzle type was less important than pairing the right nozzle configuration with the right sprayer speed to maximize the benefits of the fungicide application. If sprayer speed is the driving factor, they said using the proper nozzle may negate any potential loss of efficacy.

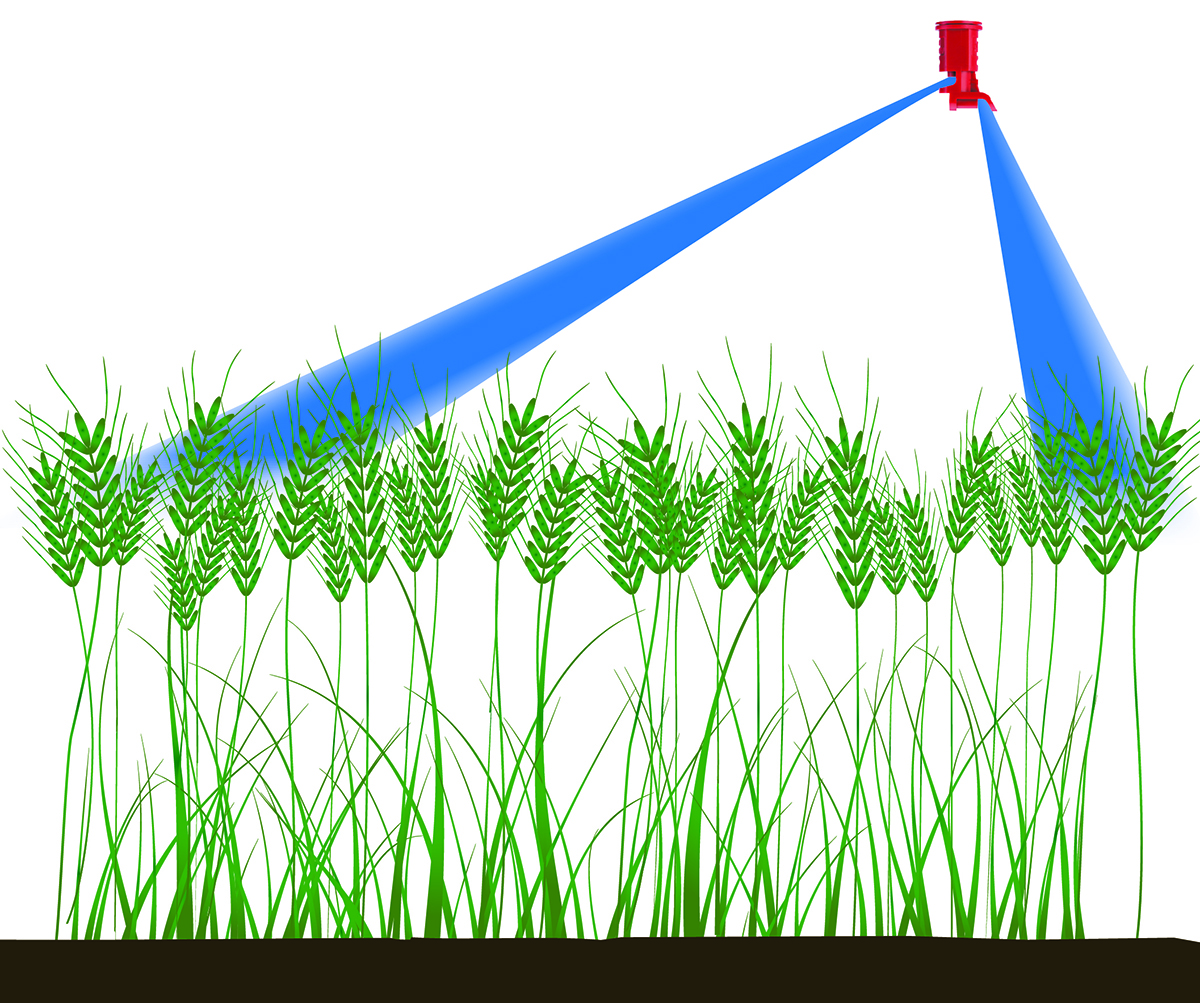

Based on their publication review, Friskop says a symmetrical dual-spray nozzle with shallow angles from vertical marginally improved coverage on the back of the grain head. However, where researchers saw the best coverage was with a single nozzle that produced an asymmetrical dual-angled spray. The forward-facing spray is steeper angled, such as 30 degrees from vertical. The backward-facing spray is shallower, such as 70 degrees from vertical. Together, they provide adequate coverage of both the front and back of the grain head. But nozzle selection is just part of the overall coverage equation, he says.

Droplet size

One of the components of fungicide application that's changed the most is droplet size, Friskop says. At one time, Extension specialists recommended fine- to medium-sized droplets of 300-350 microns.

Taking into account increased sprayer speeds, lower water volumes, and the omnipresent wind of the northern Great Plains, Friskop says he now recommends course droplet sizes to improve coverage. The courser spray droplets also are better able to maintain momentum, hit the target grain head and move past the awns to the spikelets than finer sprays.

As it is just a recommendation, Friskop says growers who have had success with smaller droplets may want to continue doing so.

Water volume

Most labels recommend applying a fungicide with at least 10 gal of water per acre (gpa), and increasing it to 20 gpa typically improves coverage. In North Dakota, Friskop says rates of 10–15 gpa are fairly common due to the logistics of hauling water to fields.

Studies have shown that the higher the water volume per acre, the better the coverage. But they also found that coverage at the highest water volumes didn't necessarily translate to greater reductions of FHB and DON.

Boom height

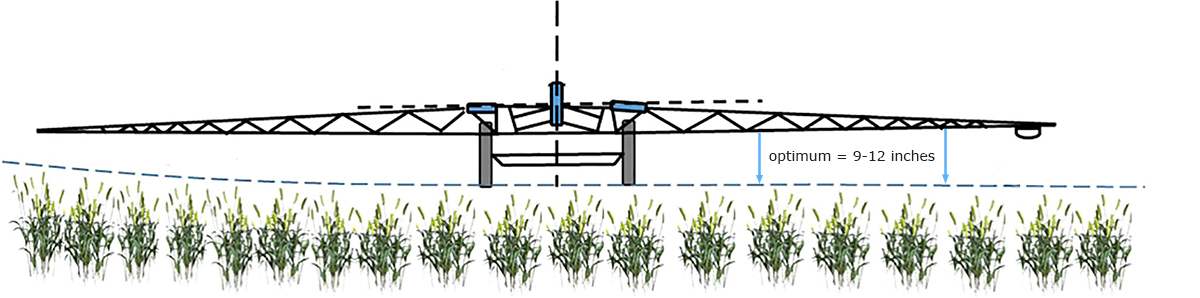

Based on research, a boom height of 9 to 12 inches above the grain heads appears optimum with 24 inches being the top threshold. Boom height above that exposes droplets to significantly more wind, increasing drift potential and decreasing fungicide coverage.

“There's a greater chance of missing that target,” Friskop says. In bumpy terrain or at high speeds, keeping the boom at optimum height may be difficult and may require the operator to slow down.

Ground speed

Most of the research that has examined fungicide efficacy on FHB has been conducted under optimum conditions and with sprayer speeds of about 6 mph, Friskop says. In fact, creating more of a real-world situation was part of the impetus behind the UK research.

“One of the challenges that we’ve discovered is we found applicators were going fast,” Stombaugh says, adding sprayers may top out at 15 mph. “A lot of the field trials were being done with backpack sprayers, and that doesn’t translate to the field.”

Studies that looked at fungicide activity when applied at higher speeds, including the UK work, have been inconclusive. Regardless of the sprayer speed, Friskop says operators need to adjust the water volume and application rate accordingly.

“If you adjust for the water rate, you can put on a pretty effective fungicide,” he says.

Self-study CEU quiz

Earn 0.5 CEUs in Integrated Pest Management by taking the quiz for the article. For your convenience, the quiz is printed below. The CEU can be purchased individually, or you can access as part of your Online Classroom Subscription.

1. Which fungicide group(s) has/have shown the greatest effectiveness for suppressing Fusarium head blight (FHB) in small grains?

a. Groups 1 (ACCase inhibitors) and 4 (synthetic auxins).

b. Group 11 (QoI/strobilurins).

c. Groups 3 (DMIs) and 7 (SDHIs).

d. Group 27 (HPPD inhibitors).

2. Which nozzle configuration is recommended for the best coverage of both the front and back of grain heads, according to research from North Dakota State University?

a. Single flat‑fan nozzle.

b. Symmetrical dual‑spray nozzle with shallow angles.

c. Asymmetrical dual‑angled nozzle (steeper forward, shallower backward).

d. Hollow‑cone nozzle.

3. In wheat, what is the most effective fungicide application window for managing FHB?

a. Pre-boot through full heading.

b. When ~15–20 % of main stems are at early flowering (Feekes 10.5.1) and up to seven days later.

c. Milk stage (Feekes 11.1).

d. Post grain fill (Feekes 11.3 and beyond).

4. To better hit moving, upright grain heads under windy Great Plains conditions, North Dakota State’s Andrew Friskop now recommends which droplet size category?

a. Ultra fine.

b. Fine.

c. Medium.

d. Coarse.

5. According to research, what boom height above the grain heads provides optimum fungicide coverage while minimizing drift?

a. 3–6 inches.

b. 9–12 inches.

c. 18–20 inches.

d. 30–36 inches.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.