From rocks to riches: The history of the United States phosphate fertilizer industry

This article was prepared as a contribution of the Western Region Nutrient Management Coordinating Committee (WERA-103). Earn 1.5 CEUs in Nutrient Management by reading this article and taking the quiz.

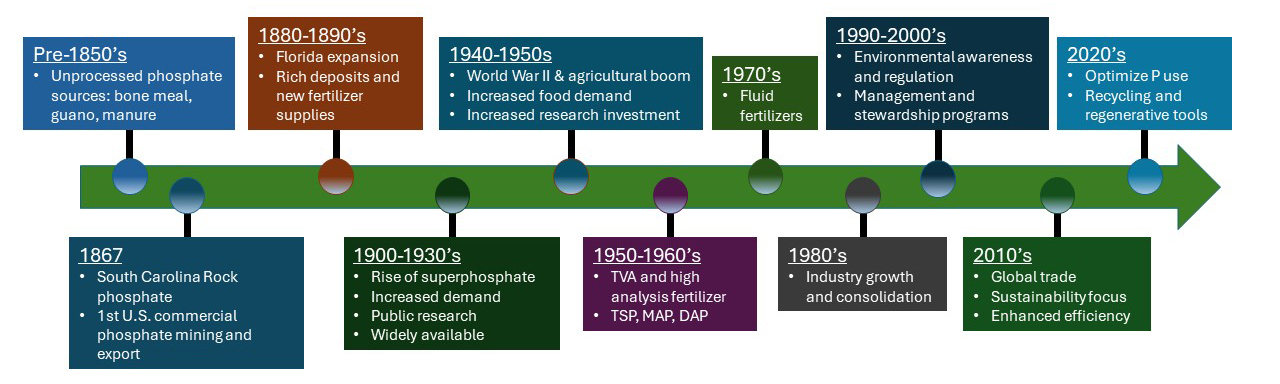

The development of the North American phosphate (P) fertilizer industry represents one of the most significant agricultural and industrial transformations in American history. From its humble beginnings in the mid-19th century to its current status as a global powerhouse, the U.S. P industry plays a crucial role in feeding the nation and the world. The evolution of the domestic P industry mirrors other industrial themes in American development: geographic expansion, scientific innovation, corporate consolidation, environmental awareness, and global economic integration.

The story of North American P fertilizer production is intrinsically linked to the transformation of farming from subsistence agriculture to large-scale commercial operations, enabling the United States to become a leading food exporter that would have been impossible without enhanced agricultural productivity (Figure 1).

Early foundations and discovery (1840s–1870s)

Phosphorus is one of the three primary nutrients essential for plant growth and nutrition of all living organisms, along with nitrogen and potassium, and is irreplaceable in the foundation of modern agricultural production.

The American P fertilizer industry began in the 1840s as agricultural scientists and farmers learned the importance of P for crop nutrition. The initial inspiration came from German scientists, such as Carl Sprengel and Justus von Liebig, who identified the essential role of phosphorus, nitrogen, and potassium in plant nutrition. Their theories reached North America through scientific publications and the emerging agricultural college system.

Canada’s involvement in the phosphate industry

For a few years in the mid-19th Century, phosphate mining was a relatively important industry in Western Quebec and Eastern Ontario, Canada. However, when larger and less expensive sedimentary deposits were discovered elsewhere in North America, these P mining sites were no longer commercially competitive.

There is still on-going interest in developing the Canadian P industry, with projects underway in British Columbia (Canadian Phosphate Limited) and in Quebec (Arianne Phosphate Inc).

Farmers had already observed that P-rich bone meal, wood ash, and manures improved plant growth, but the specific nutrients were not yet identified. During U.S. colonial times, slash and burn agriculture was commonly employed to clear land and enrich the soil with nutrients from the residual ash. One study reported that forest ash contained 11 kg P/ha and 27 kg N/ha after burning, of which more than half was blown from the field in wind (Giardina et al., 2000).

During this period, slash and burn techniques forced inland migration from the Atlantic Coast as agricultural fields were successively exhausted of their nutrients with no means of restoring the fertility. When added to soil, the liming effects from ash and input of mineral P and K made it a good amendment for growing a N-fixing crop.

In the early 1800’s, it was observed that bones were beneficial for plant growth. As the value of ground bones was recognized as a P source, the demand grew quickly. Unprocessed bones (hydroxyapatite; Ca5F(PO4)3OH) were crushed and applied to the soil at a rate of one t/ac or more. In England, the demand for bones outstripped domestic supply and by 1815, bones were imported from continental Europe, reaching a maximum of 30,000 t/yr (Nelson, 1990).

Observations that not all bones were equally effective as a plant-nutrient source led to experimentation to acidify the bones before adding them to soil. One early British innovator, John Lawes, applied raw bone to his fields without seeing additional crop growth. This led him to experiment with treating bones with sulfuric acid, which proved to be very effective for crops. In 1842 he was granted a patent for “superphosphate of lime”, composed of calcium hydrogen phosphate and calcium sulfate (see equation below):

The manufacturing of superphosphate quickly spread around the world and this marked the beginning of the modern fertilizer industry (Mikkelsen, 2019).

The first commercial P fertilizer production in the United States began with processing bones, which were ground and treated with sulfuric acid. Companies in Baltimore, Philadelphia, and other East Coast cities established small-scale operations to serve local farmers. These early enterprises were typically small, family-owned businesses that processed bones collected from slaughterhouses and butcher shops (Figure 2). Not surprisingly, major U.S. meat processing companies and slaughterhouses later became major fertilizer manufacturers, distributing both N- and P-based products for crop production.

Mineral deposits of phosphate rock (apatite) were later developed and substituted for bones in production of superphosphate. The P fertilizer industry entered the modern era as phosphate rock sources became readily available and accessible from geologic deposits around the world (e.g., England, 1847; Norway, 1851; France, 1856; USA, 1867; Tunisia, 1897, Morocco, 1921; Russia, 1930).

All common P fertilizers are now produced from phosphate rock as the starting material (Figure 3). Most sources of phosphate rock are too insoluble for direct use as a P source for plants. Phosphate rock from a few geologic deposits is suitable for direct application, especially if used for perennial crops growing in acidic soils, where the acidity and low Ca concentrations help speed rock dissolution and P release.

The rock phosphate industry begins (1867)

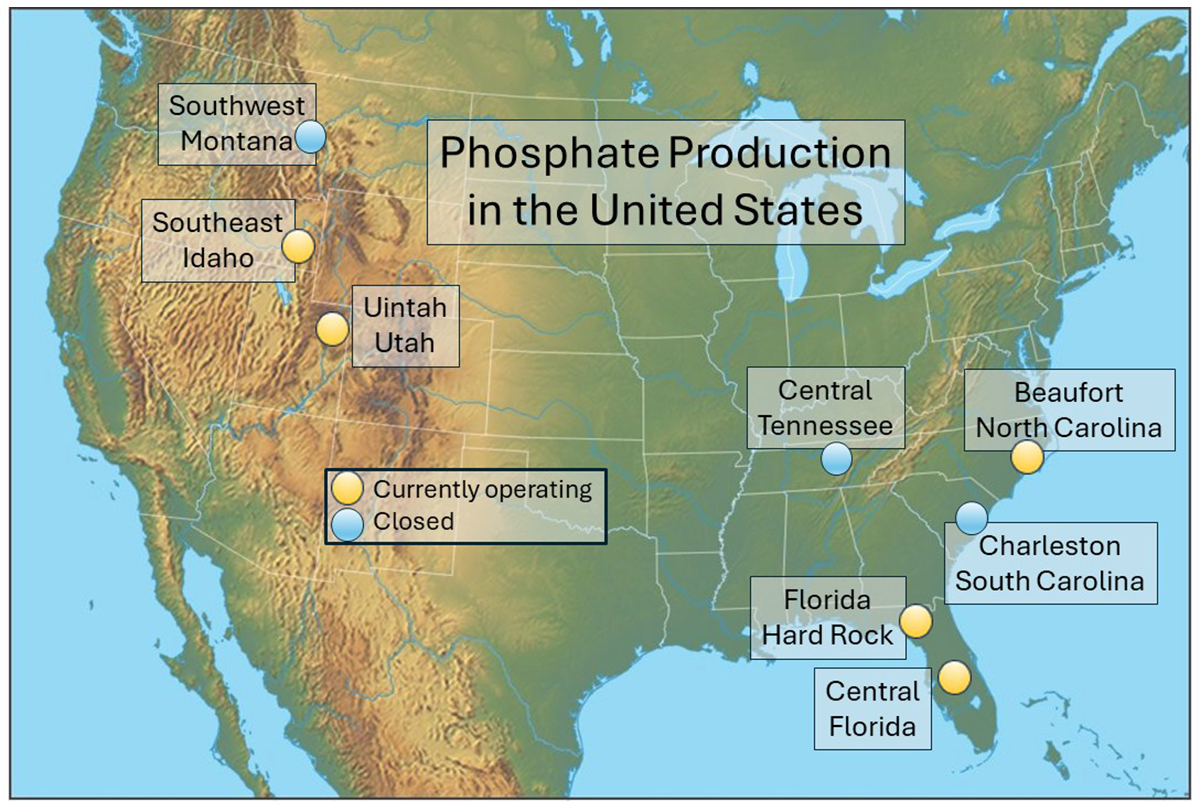

The discovery of natural phosphate rock deposits in the U.S. would soon revolutionize the domestic industry. In 1867, significant phosphate deposits were discovered in South Carolina, near Charleston. This discovery marked the beginning of phosphate rock mining in the United States and established South Carolina as the first major center of American P production.

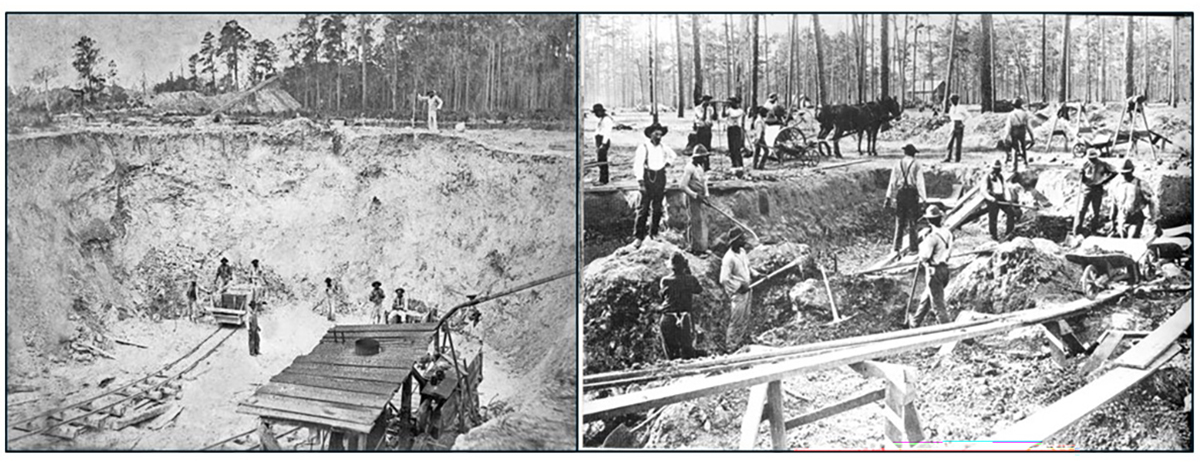

The South Carolina P deposits were found in two forms: river-rock phosphate, discovered in riverbeds and marshes, and land-rock phosphate, located in surface and underground deposits. The river rock deposits were particularly valuable because they were accessible with hand labor and required minimal processing (Figure 4). By the 1870s, numerous companies had established operations in the South Carolina Low Country, creating the first major P-mining region in the United States and providing valuable post-war income.

The Florida phosphate boom (1880s-1920s)

The industry experienced its next expansion with the discovery of P deposits in the Peace River region of central Florida in 1881, followed by the identification of phosphate deposits in the northern part of the state. These discoveries would fundamentally alter the geography and scale of American P production.

Florida's P deposits were far more extensive and accessible than those in South Carolina (Figure 5). The state's phosphate occurred in several forms: river pebble phosphate, which could be dredged from rivers and streams; land pebble phosphate, found in surface deposits; and hard rock phosphate, located in underground formations at a depth ranging from 15 to 50 feet. The abundance and quality of Florida's P resources quickly attracted significant capital investment and technological innovation.

The development of Florida's phosphate industry coincided with the expansion of the railroad system, which provided crucial transportation links to markets throughout the United States. Towns like Bartow, Lakeland, and Mulberry emerged as centers of P mining and processing, fundamentally transforming the economic landscape of central Florida.

During this period, phosphate mining techniques became increasingly sophisticated. Steam-powered dredges were developed to extract river-pebble phosphate, while land pebble operations employed hydraulic mining methods. Surface phosphate mining continues to use dragline techniques to excavate the ore and load it in slurry pipelines for transport to the beneficiation plant. The industry also pioneered new methods for washing, screening, and grading phosphate rock to meet specifications of fertilizer manufacturers. Mosaic and Nutrien are the major companies with active mines in Florida.

Phosphate discovery expands

Phosphate rock deposits were discovered in middle Tennessee in the mid 1800’s, and commercial mining began in the 1890’s. Tennessee quickly became a leading U.S. P-fertilizer producer. By the 1930’s, assistance from the Tennessee Valley Authority also helped their processing practices and profitability. By the 1950’s, after larger and more profitable P resources were discovered in Florida and the Western US, production in Tennessee slowed and then totally ceased by 1991.

North Carolina sedimentary deposits of rock phosphate near Aurora, NC are relatively shallow, but they were not commercially developed until the 1960’s by Texas Gulf Sulfur, then Potash Corporation of Saskatchewan (PCS), and it is now operated by Nutrien (Figure 6). The site soon developed into one of the largest P mines in the world. Its location in the Pamlico River Basin led to heavy regulation and the requirement for strict wetland reclamation protocols.

Western U.S. deposits from the “Phosphoria formation” are found in southeastern Idaho, western Wyoming, northern Utah, and southwest Montana. This resource was discovered in the early 1900’s and commercial development began in the middle of the 20th century. Several open-pit mines exist across the region, with most of the current production centered near Soda Springs, Idaho, currently operated by JR Simplot and Itafos, and near Vernal, Utah.

Technological innovation and industrial growth (1900s–1940s)

The early 20th century witnessed significant technological advances in P fertilizer production. The development of new chemical processes for converting phosphate rock into soluble fertilizers revolutionized the industry. The contact process for making sulfuric acid, essential for creating superphosphate fertilizers, was perfected during this period, allowing for more efficient and cost-effective fertilizer manufacturing.

World War I marked a turning point for the American P industry. The disruption of European fertilizer supplies created unprecedented demand for American-produced fertilizers. The federal government recognized P as a strategic resource and provided support for expanded production. This period saw construction of larger, more efficient processing plants and consolidation of smaller companies into larger corporations.

The 1920s and 1930s brought further consolidation and technological innovation. Companies like American Agricultural Chemical Co. (later acquired by Continental Oil Co.) and International Minerals and Chemical (IMC) Corp. emerged as major players in the industry. These corporations invested heavily in research and development, leading to improved fertilizer formulations and more efficient production processes.

The Great Depression initially reduced demand for fertilizers as farmers struggled with low crop prices and limited capital. However, federal agricultural programs, including those established by the New Deal, ultimately supported the industry by providing assistance to farmers and promoting soil conservation practices that emphasized proper fertilization.

World War II and post-war expansion (1940s–1970s)

World War II dramatically increased demand for P fertilizers as the United States sought to maximize agricultural production to feed both domestic and allied populations. The federal government recognized P as a strategic material and supported expansion of mining and processing. New production facilities were constructed, and existing operations were expanded to meet the wartime demand.

The post-war period brought unprecedented growth in American agriculture, driven by mechanization, improved crop varieties, and increased fertilizer use. The P fertilizer industry benefited enormously from this agricultural revolution.

During the 1950s and 1960s, the industry continued to consolidate as smaller companies were acquired by larger corporations. Technological advances included development of new fertilizer formulations, improved mining techniques, and more efficient transportation methods. The construction of specialized P terminals at ports like Tampa, Savannah, and New Orleans facilitated export growth.

Florida solidified its position as the dominant P-producing state during this period. The development of large-scale surface mining operations in central Florida’s Bone Valley region established the area as the heart of American P production. Companies like IMC Corp., Borden, W.R. Grace & Co., and Agrico Chemical Co. operated large mining and processing facilities that transformed the landscape of central Florida.

Cadmium in phosphate fertilizer

Cadmium is a naturally occurring impurity in phosphate rock, and its concentration in P fertilizer varies depending on the source of the rock and the manufacturing process. The European Union has a regulatory limit of 60 mg Cd/kg P2O5 in P fertilizers, while no such limits exist in the U.S.

U.S. phosphate rock from the eastern U.S. generally contains lower cadmium concentrations than the western U.S. ores. For example, Florida rock P generally contains between 2 to 15 mg Cd/kg, while western ores typically range from 50 to 150 mg Cd/kg (USEPA, 1977). Other geologic constituents such as arsenic, lead, and uranium may be found in some ores.

The Tennessee Valley Authority (TVA) and land-grant universities continued to advance fertilizer production and agronomic use in the 1960s. They promoted high-analysis fertilizers, which delivered more nutrients per unit of product, reducing transportation and labor costs. This included the development of important P fertilizers such as diammonium phosphate (DAP; 18-46-0), monoammonium phosphate (MAP; 11-52-0) and fluid ammonium polyphosphate (APP; 10-34-0).

Phosphate rock is no longer sold directly in significant quantities for direct application. Instead, it is converted into phosphoric acid, which is then reacted with ammonia to produce DAP and MAP. However, there is still a significant amount of rock P that is imported into the U.S. for the production of domestic fertilizer.

Expansion, consolidation, and oversight (1970s–1990s)

The 1970s marked a time of increased environmental scrutiny of the P industry. The environmental movement started to focus attention on environmental impacts of industrial agriculture, including fertilizer production and use. The P industry began to face criticism for its effects on water quality, air pollution, and land use surrounding the mining sites.

Phosphate fertilizer production peaked in 1980, when domestic phosphate rock production reached approximately 54 million metric tons (USGS, 2024). Since that time, it has continually declined due to gradual depletion of high-grade domestic reserves (especially in Florida), tighter environmental regulations, and greater competition from international suppliers.

Phosphate mining operations were particularly scrutinized for their environmental impacts. Surface mining activities disturbed thousands of acres of land, often disrupting wetlands and natural habitats. The industry's practice of storing phosphogypsum, a potentially radioactive byproduct of P fertilizer production, in large stacks raised concerns about groundwater contamination and potential radioactive exposure.

Federal environmental legislation, including the Clean Air Act, Clean Water Act, and Resource Conservation and Recovery Act, imposed new regulatory requirements on P-producing companies. These regulations required significant investments in pollution control equipment, environmental monitoring, and land reclamation. Some companies struggled to meet these requirements, leading to plant closures and further industry consolidation from 15 to 20 P-producing companies in the mid-1970’s to only a few now.

The industry responded to environmental challenges by investing in cleaner production technologies and improved environmental management practices. Companies that continued successfully developed methods for recycling process water, reducing air emissions, and reclaiming mined lands.

Continued consolidation and global competition (1990s–present)

The final decades of the 20th century brought additional changes to the American P fertilizer industry. Increased global competition, particularly from producers in Morocco, China, and other countries with lower production costs, pressured American companies to improve efficiency and reduce costs. Many smaller operations were unable to compete and closed, while larger companies consolidated operations and invested in new technologies.

International trade

For most of the 20th century, the U.S. was a major global producer of P fertilizer and often a significant exporter. The U.S. was the world’s leading P producer until 2006, when China surpassed it.

In 1996, the US first became a net importer of phosphate rock (to be processed in the U.S.) for the first time. Since then, P imports of rock or finished fertilizer account for between 6 to 16% of the total U.S. consumption. Today, the U.S. produces about 12% of global phosphate rock, with most mining concentrated in Florida, North Carolina, Idaho, and Utah.

U.S. fertilizer imports are currently dominated by Morocco. China was previously an important source of P fertilizer in the US, but internal domestic policies have reduced their exports. A variety of suppliers have emerged to fill this import gap, such as Saudi Arabia, Jordan, Egypt, Tunisia, and Peru. Russian P exports are also significant, but global events and tariffs have changed their marketplace acceptance in the U.S.

Several major corporate acquisitions reshaped the entire fertilizer industry during this period. Cargill Inc. merged with IMC in 2004, creating Mosaic, one of the world's largest P producers. Other significant acquisitions included PCS's purchase of Arcadian Corporation and CF Industries' acquisition of Terra Industries. These consolidations were driven by the need to achieve economies of scale and compete in increasingly global markets. The industry further consolidated with the merger of PCS and Agrium in 2018 forming Nutrien. Current major P fertilizer producers (Mosiac, Nutrien, Simplot) are vertically integrated operations, controlling everything from mining to granulation and sales to streamline efficiency.

Despite these challenges, the American P industry maintains its position as a significant global producer. Florida remains the dominant producing state, accounting for approximately 80% of U.S. phosphate rock production. Other producing states include North Carolina, Idaho, Montana, and Utah, though their production levels are smaller than Florida's.

The industry also faced new challenges from changing agricultural practices and environmental concerns. Development of precision agriculture techniques allowed farmers to apply fertilizers more efficiently, potentially reducing total demand. Concerns about water quality, particularly related to phosphorus runoff and eutrophication of water bodies, led to new regulations and voluntary programs to reduce fertilizer use.

Current status and future outlook

Today, the United States P fertilizer industry operates in a complex global marketplace characterized by volatile commodity prices and political shocks, environmental regulations, and changing agricultural practices.

The modern industry faces several significant challenges. Environmental regulations continue to impose costs and operational constraints, particularly related to water quality protection, mine land reclamation, and phosphogypsum storage, a significant logistical and environmental challenge. Global competition remains intense. Additionally, concerns about the sustainability of current agricultural practices and environmental impacts of fertilizer use continue to influence public policy and consumer preferences.

The domestic industry has responded to these challenges through continued technological innovation, operational efficiency improvements, and strategic positioning in global markets. The fertilizer industry has invested in precision application technologies, enhanced-efficiency fertilizers, and sustainable production practices. Recycling of P from various waste streams of other industries, such as waste-water treatment and animal manures, represents an opportunity for technological advancement in conserving P resources - but recycling costs, technological development, logistics, and consistency of supply and source quality remain challenging.

The development of new fertilizer formulations that reduce environmental impacts while maintaining agricultural productivity represents a key focus area for research and development. A variety of new formulations and additives claiming improved P availability and P-use efficiency have been introduced to the market.

Looking toward the future, the American P fertilizer industry faces both opportunities and challenges. Growing global population and rising food demand are expected to support long-term growth in fertilizer consumption. However, the industry must continue to address environmental concerns, adapt to changing agricultural practices, and compete effectively in global markets.

Conclusion

The history of the United States P fertilizer industry reflects broader themes in American economic and social development. From its origins in small-scale bone processing operations to its current status as a global industry, P fertilizer production has been shaped by scientific discovery, technological innovation, corporate consolidation, environmental awareness, and global competition. Phosphate fertilizers have played a crucial role in supporting the productivity gains that allow the United States to help feed a growing global population as a major food exporter.

Giardina, C. P., Sanford, R. L., Dockersmith, I. C., & Jaramillo, V. J. (2000). The effects of slash burning on ecosystem nutrients during the land preparation phase of shifting cultivation. https://doi.org/10.1023/A:1004741125636

Mikkelsen, R. (2019). Sources of phosphorus for plants: Past, present, and future. Better Crops, 17–21. International Plant Nutrition Institute. https://www.cabidigitallibrary.org/doi/pdf/10.5555/20193325369

Nelson, L. B., & Parker, J. H. (1990). History of the U.S. fertilizer industry. Tennessee Valley Authority, Muscle Shoals, AL.

Roberts, T. (2019). Phosphorus: Past history and contributions to the global food supply. Better Crops, 103(1), 6–8. International Plant Nutrition Institute.

USEPA. (1977). Chemical technology and economics in environmental perspectives: Task VI – Cadmium in phosphate fertilizer production. U.S. Environmental Protection Agency. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=9100OPEU.TXT

USGS. (2024). Phosphate rock – Historical statistics (Data Series 140). U.S. Geological Survey. https://www.usgs.gov/media/files/phosphate-rock-historical-statistics-data-series-140

Self-study CEU quiz

Earn 1.5 CEUs in Nutrient Management by taking the quiz for the article. For your convenience, the quiz is printed below. The CEU can be purchased individually, or you can access as part of your Online Classroom Subscription.

- The American phosphate industry began primarily by processing

a. phosphate rock.

b. bone meal.

c. synthetic fertilizers.

d. manure.

- In which U.S. state were significant phosphate rock deposits discovered in 1867?

a. Florida.

b. South Carolina.

c. Tennessee.

d. North Carolina.

- Florida has been the dominant phosphate-producing state in the U.S. since the late 19th century.

a. True.

b. False.

- Which Canadian provinces had early phosphate mining operations?

a. Ontario and British Columbia.

b. Alberta and Quebec.

c. Manitoba and Saskatchewan.

d. Quebec and Ontario.

- What is the primary source of modern phosphate fertilizers?

a. Phosphate rock.

b. Bone meal.

c. Synthetic phosphorus compounds.

d. Manure.

- Which process is essential for converting phosphate rock into soluble fertilizer?

a. Steam distillation.

b. Electrolysis.

c. Contact process for sulfuric acid.

d. Ammonia synthesis.

- Cadmium concentrations in phosphate fertilizers are strictly regulated in the United States.

a. True.

b. False.

- Cadmium concentrations in phosphate rock from western U.S. ores are generally

a. lower than Florida’s.

b. about the same as Florida’s.

c. higher than Florida’s.

d. negligible.

- When did the U.S. first become a net importer of phosphate rock?

a. 1980.

b. 1996.

c. 2006.

d. 2010.

- What type of fertilizer is produced by reacting phosphoric acid with ammonia?

a. Superphosphate.

b. Monoammonium phosphate (MAP).

c. Bone meal fertilizer.

d. Potash.

- Which U.S. phosphate-producing state’s operations ceased by 1991 due to competition from larger deposits elsewhere?

a. Tennessee.

b. Florida.

c. North Carolina.

d. Idaho.

- The “Phosphoria formation” is primarily found in

a. Florida.

b. South Carolina.

c. Western U.S. (Idaho, Wyoming, Utah, Montana).

d. North Carolina.

- Diammonium phosphate (DAP) contains which N-P-K ratio?

a. 10-34-0.

b. 11-52-0.

c. 18-46-0.

d. 20-20-20.

- Which country surpassed the U.S. as the world’s leading P producer in 2006?

a. Morocco.

b. China.

c. Saudi Arabia.

d. Russia.

- The early U.S. P fertilizer industry was closely linked to

a. the coal industry.

b. meat processing and slaughterhouses.

c. cotton plantations.

d. textile manufacturing.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.