Is strip-till a useful soil management tool for Wisconsin corn and soybean production?

Alleviation of cold, wet, and compacted soils is of great importance for earlier planting that can lead to improved yield in short growing season environments. Strip-till adoption in corn has increased as a sustainable means to improve soil conditions and yield; however, the response of soybean to strip-till has been less consistent. The objectives of this research were to (1) quantify the effect of strip-till, row spacing (soybean only), crop rotation (corn only), fertilizer placement, and in-furrow fungicide on corn and soybean plant population, canopy coverage, and grain or seed yield; (2) evaluate strip-till, row spacing, fertilizer placement, and in-furrow fungicide on soil temperature and penetration resistance; and (3) determine best management recommendations for strip-till use in Wisconsin corn and soybean production systems.

Wisconsin corn and soybean growers have steadily improved grain and seed yield over the past decade; however, they are annually challenged with yield-suppressing conditions such as cold and dense soils, difficult early-season planting conditions, and highly erodible landscapes. To resolve these issues, many growers utilize tillage as a soil management technique. However, the combination of tillage and erodible landscapes can increase erosion (Seta et al., 1993). Current recommendations for corn and soybean production in a corn–soybean (CS) rotation in Wisconsin are to utilize no-till 30- and 15-inch row spacings, respectively. Due to a perceived yield plateau to row crop no-till soybean and corn, growers in Wisconsin have become increasingly interested in strip-till as a management tool to improve early-season planting conditions while maintaining soil structure and health (Allmaras & Dowdy, 1985).

By combining strip-till with different commonly used corn and soybean management practices, the objectives were to (1) quantify the effect of strip-till, row spacing (soybean only), crop rotation (corn only), fertilizer placement, and in-furrow fungicide on corn and soybean plant population, canopy coverage, and grain or seed yield; (2) evaluate strip-till, row spacing, fertilizer placement, and in-furrow fungicide on soil temperature and penetration resistance; and (3) determine best management recommendations for strip-till use in Wisconsin corn and soybean production systems.

In a Bean Pod

- Strip-till reduced penetration resistance in the root zone of strip-till rows.

- Soybean seed yield was similar between the strip-till 30-inch row and no-till 15-inch row spacings.

- Strip-till and banded fertilizer increased corn grain yield.

- Crop rotation increased corn plant population and yield.

This article is adapted from an article originally published in Agronomy Journal. View the original article at https://doi.org/10.1002/agj2.20067

Experiment 1: Small-Plot Trial

Materials and Methods

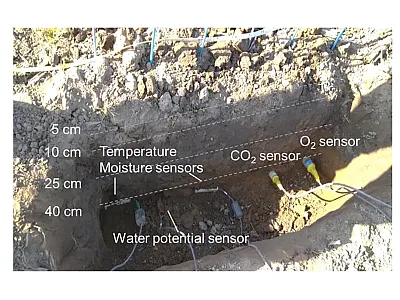

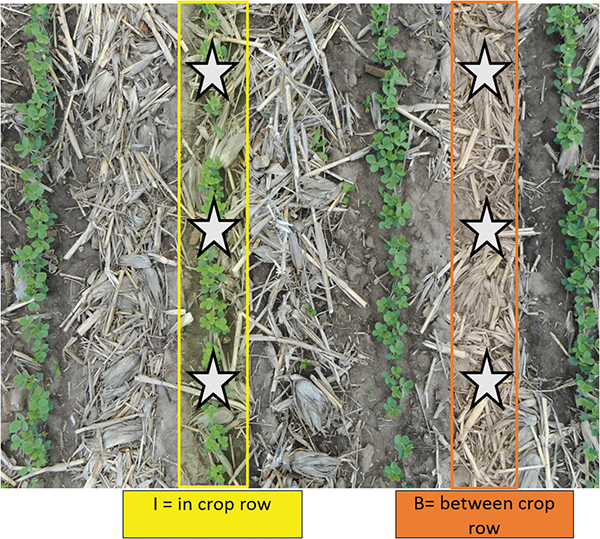

Small-plot trials were conducted in Arlington, WI during the 2016, 2017, and 2018 growing seasons. The site included a corn–soybean rotation in all phases and a corn-on-corn sequence present since 2001. Management practices for this study consisted of 12 combinations of spring strip-till or no-till, deep-banded or broadcast fertilizer, and soybean 15- or 30-inch row spacings and in-furrow fungicide (Priaxor at 6.0 fl oz per acre) or a non-treated control. Soybean was planted at 140,000 seeds/ac into all plots in either 15- or 30-inch row spacing. For strip-till plots in soybean, 30-inch row spacings were planted directly over strip-till rows whereas every other row of the 15-inch row spacings was planted directly over strip-till rows. To avoid planting over corn stalks from the previous year, 30-inch plots were offset from the center of the previous-year corn row by 15 inches whereas 15-inch plots were offset by 7.5 inches. Strip-till was applied using a four-row, 76-cm spacing Remlinger unit with two Grandy fertilizer boxes, which allowed for deep-banded 15–38-131 lb/ac NPK fertilizer application. The same fertilizer rate was also applied as the broadcast treatment. Nitrogen was sidedressed at 190 and 160 lb/ac in the continuous corn and corn–soybean rotation, respectively. All corn plots were planted in 30-inch row spacing directly over 30-inch strip-till rows or in no-till. Soil temperature and penetration resistance were collected as well as plant population, canopy coverage, and yield. Soil penetration resistance was collected using a cone penetrometer in crop rows and between crop rows. Soybean seed yield was corrected to 13% moisture, and corn grain yield was corrected to 15.5% moisture.

Results and Discussion

Soil Temperature

No differences in soil temperature were observed between strip-till and no-till plots for any date during the 2016, 2017, or 2018 growing seasons; therefore, data for this measurement are not shown.

Soil Penetration Resistance

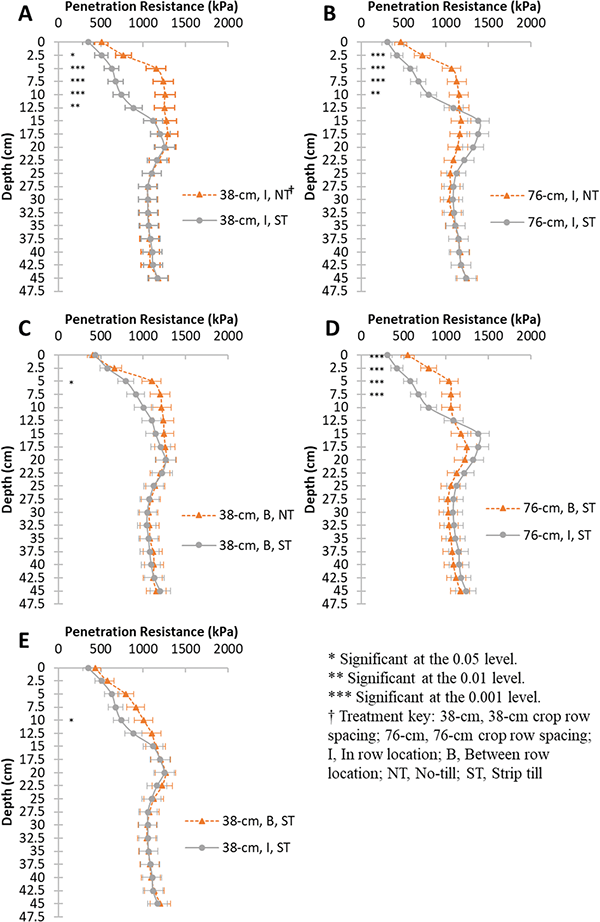

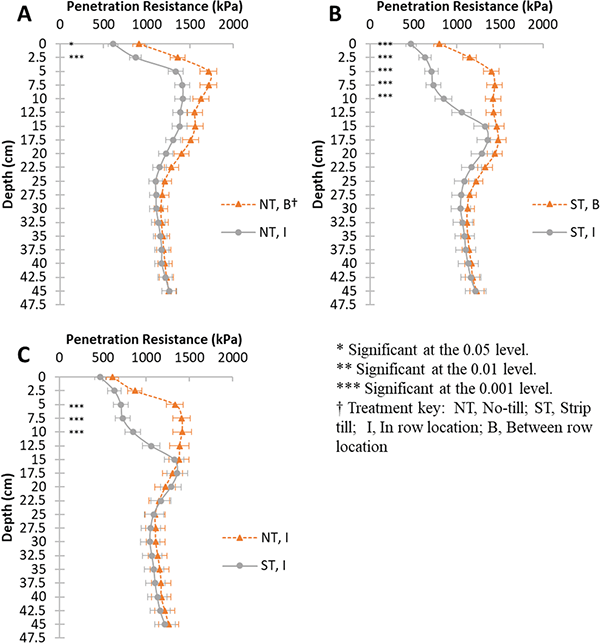

In soybean, the three-way interaction between tillage × row location × row spacing significantly affected soil penetration resistance (Figure 1). Across row spacings and in the in-row location, a reduction in penetration resistance was observed in the upper 12.5 cm (Figure 1A, B, D). In between-row locations, there were no differences in penetration resistance by depth in 30-inch row spacings, and one significant difference was observed at the 5-cm depth in the 15-inch row spacing (Figure 1C). This suggests that penetration resistance in between-row location in strip-till 15-inch row spacing was comparable to no-till. The only difference in strip-till 15-inch row spacing between in-row and between-row locations was observed at a 10-cm depth (Figure 1E). Planter disturbance likely contributed to similar penetration resistance values in in-row and between-row locations in the upper 7.5 cm. Overall, penetration resistance was decreased in strip-till rows, resulting in a more favorable seedbed for soybean production.

In corn, within the corn–soybean rotation, a significant interaction between tillage × row location was observed (Figure 2). Within no-till plots, between-row locations had greater penetration resistance than in-row locations at the 0- to 2.5-cm depths, possibly due to disturbance from planting in the upper 5 cm (Figure 2A). Within strip-till locations, in-row location had significantly less penetration resistance from 0 to 10 cm—a reduction likely caused by the strip-till row unit (Figure 2B). A similar resistance difference was observed when comparing no-till and strip-till within the in-row location between 5 and 10 cm (Figure 2C). Again, planter disturbance in the no-till row likely decreased disturbance in the top 2.5 cm, resulting in no response. These results agree with similar studies on penetration resistance in strip-till and no-till systems that also found a reduction in penetration resistance from strip-till in the upper 10 to 20 cm of soil (Licht & Al-Kaisi, 2005).

Plant Population

In soybean, the main effect of row spacing was significant. Plant population was 9,100 plants/ac (8.0%) greater in 30-inch row spacing than in 15-inch row spacing. Plants in 30-inch rows likely benefited more from intra-plant assistance during emergence due to their reduced intra-row spacing.

In corn, crop rotation and fertilizer were found to be significant factors (Table 1). Banded fertilizer had 900 plants/ac (2.5%) greater plant population than surface-applied fertilizer (Table 1). Compared with continuously planted corn, CS-rotated corn had 1,300 plants/ac (3.8%) greater plant population (Table 1). Few studies have included the interaction of in-furrow fungicide with crop rotation; however, studies have found little response of plant population with crop rotation (Pedersen & Lauer, 2003). Improving stand viability is important as plant populations and corn grain yield are positively correlated (Pedersen & Lauer, 2002).

Table 1. Fertilizer placement and crop influence on corn plant population from 2016–2018

| Fertilizer placement and crop | Plant population (plants/ac) |

|---|---|

| Fertilizer placementa | |

| Banded | 33,300ab |

| Surface | 32,400b |

| Cropc | |

| C | 33,300a |

| CC | 32,000b |

Canopy Coverage in Soybean

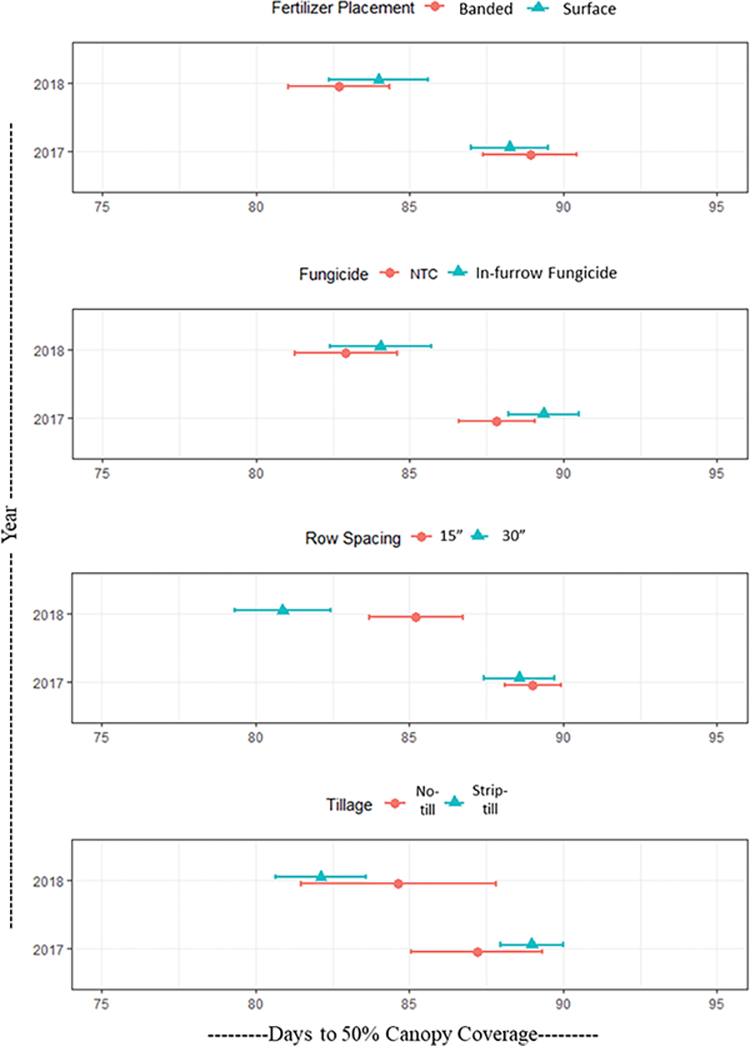

Canopy reached 50% coverage earlier in 2018 than in 2017, likely due to an earlier planting date in 2018 (Figure 3). In 2017, 50% canopy coverage was reached ∼5 days earlier in 30-inch row spacing than in 15-inch row spacing. This result contradicts most research in soybean canopy coverage, which suggests earlier canopy coverage and greater light interception in narrow row spacings (i.e., 15 inches) (Wells, 1991). Increased plant population in 30-inch row spacings could have contributed to this result. Strip-till and fertilizer placement response to canopy coverage varied by year, and no response was observed from in-furrow fungicide use.

Yield

In soybean, banded fertilizer resulted in 4.4 bu/ac (6.5%) greater yield than surface-applied fertilizer; however, without a deep-banded no-till treatment, it is not possible to compare results to similar studies (Farmaha et al., 2011) (Table 2). The greatest soybean seed yield within the crop row spacing × tillage × in-furrow fungicide interaction was obtained by combining strip-till, in-furrow fungicide, and 15-inch row spacing. However, this combination resulted in similar yield to no-till, non-treated control, and 15-inch row spacing and to strip-till, non-treated control, and 15-inch row spacing (Table 2).

Table 2. Fertilizer placement and tillage × fungicide × row spacing influence on soybean seed yield from 2016–2018

| Fertilizer placement and tillage × fungicide × row spacing | Seed yield (bu/ac) | ||

|---|---|---|---|

| Fertilizer placementa | |||

| Banded | 68.7ab | ||

| Surface | 64.3b | ||

| Tillage × fungicide × row spacec | |||

| ST | Fungicide | 15 | 70.5a |

| NT | NTC | 15 | 67.2ab |

| ST | NTC | 15 | 66.9ab |

| ST | Fungicide | 30 | 66.1b |

| ST | NTC | 30 | 65.9b |

| NT | Fungicide | 15 | 65.7bc |

| NT | Fungicide | 30 | 61.1c |

| NT | NTC | 30 | 56.1d |

In corn, strip-till yielded 13.1 bu/ac (5.7%) greater than no-till, and banded fertilizer yielded 11.4 bu/ac (4.9%) higher than surface-applied fertilizer (Table 3). Corn–soybean × in-furrow fungicide had greater grain yield than corn–soybean × non-treated control, corn–corn × non-treated control, and corn–corn × in-furrow fungicide (Table 3). The effect of in-furrow fungicide depended on crop rotation and likely was a result of a differing pathogen load between rotations (Peters et al., 2003). In general, CS-rotated corn yielded greater than corn–corn. A 9.3% yield increase was attributed to the CS-rotated corn compared with continuous corn.

Table 3. Fertilizer placement, tillage, and crop ×fungicide influence on corn grain yield from2016–2018

| Fertilizer placement, tillage, and crop × fungicide | Grain yield(bu/ac) | |

|---|---|---|

| Fertilizer placementa | ||

| Banded | 232.5ab | |

| Surface | 221.1b | |

| Tillagec | ||

| ST | 229.2a | |

| NT | 216.1b | |

| Crop × fungicided | ||

| CS | Fungicide | 237.5a |

| CS | NTC | 229.6b |

| CC | NTC | 216.9bc |

| CC | Fungicide | 215.3c |

Conclusion

In soybean, yield response to strip-till was affected by other management practices. Based on our results, in Wisconsin, farmers utilizing 15-inch row spacings should consider using no-till and surface-applied fertilizer while farmers utilizing 30-inch row spacing should consider strip-till and banded fertilizer. In-furrow fungicide yield response was management specific, and more research is needed to make a clear recommendation for its use in soybean production. Based on our data, strip-till can be used to overcome the yield deficit normally associated with 30-inch soybean row spacing; however, no-till and 15-inch row spacing is still recommended for soybean production in Wisconsin.

In corn, greater plant populations were observed in the CS rotation compared with the continuous corn rotation. Furthermore, yields in the CS rotation were greater than the continuous corn rotation. Use of in-furrow fungicide improved yield in CS rotation; however, no difference was observed in the continuous corn rotation. Our data suggest that strip-till and banded fertilizer are useful management practices to improve corn grain yield instead of no-till and broadcast fertilizer.

Dig deeper

Allmaras, R. R., & Dowdy, R. H. (1985). Conservation tillage systems and their adoption in the United States. Soil and Tillage Research, 5(2), 197–222. https://doi.org/10.1016/0167-1987(85)90030-3.

Farmaha, B. S., Fernández, F. G., & Nafziger, E. D. (2011). No-till and strip-till soybean production with surface and subsurface phosphorus and potassium fertilization. Agronomy Journal, 103(6), 1862–1869. https://doi.org/10.2134/agronj2011.0149.

Licht, M. A., & Al-Kaisi, M. (2005). Strip-tillage effect on seedbed soil temperature and other soil physical properties. Soil and Tillage Research, 80(1-2), 233–249. https://doi.org/10.1016/j.still.2004.03.017.

Pedersen, P., & Lauer, J. G. (2002). Influence of rotation sequence on the optimum corn and soybean plant population. Agronomy Journal, 94(5), 968–974. https://doi.org/10.2134/agronj2002.0968).

Pedersen, P., & Lauer, J.G. (2003). Corn and soybean response to rotation sequence, row spacing, and tillage system. Agronomy Journal, 95(4), 965–971. https://doi.org/10.2134/agronj2003.9650.

Peters, R., Sturz, A., Carter, M., & Sanderson, J. (2003). Developing disease-suppressive soils through crop rotation and tillage management practices. Soil and Tillage Research, 72(2), 181–192. https://doi.org/10.2134/agronj2002.0968.

Seta, A. K., Blevins, R. L., Frye, W. W., & Barfield, B. J. (1993). Reducing soil erosion and agricultural chemical losses with conservation tillage. Journal of Environmental Quality, 22(4), 661–665. https://doi.org/10.2134/jeq1993.00472425002200040004x (accessed 14 Mar. 2019).

Wells, R. (1991). Soybean growth response to plant density: Relationships among canopy photosynthesis, leaf area, and light interception. Crop Science, 31(3), 755–761. https://doi.org/10.2135/cropsci1991.0011183X003100030044x (accessed 4 Jan. 2018).

Volodymyr Nadykto, Rolandas Domeika, Gennadii Golub, Savelii Kukharets, Tetiana Chorna, Jonas Čėsna, Taras Hutsol, Research on a Machine–Tractor Unit for Strip-Till Technology, AgriEngineering, 10.3390/agriengineering5040134, 5, 4, (2184-2195), (2023).

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.