Beer and barley, whiskey and corn: Breeding plants for tastier craft beverages

Any time I'm in need of a decent bottle of wine, I beeline to that waving sign, demarking the “Italian” vino from “French” and “New Zealand” from “California.” There's no definitive reason for my preference—some small bias from a semester spent abroad coupled with the force of habit, perhaps? But there's just something about those grapes.

The idea that the unique environment in which ingredients are grown influences the flavor of the final product is known as “terroir,” and researchers are now considering that it may play a role in more than just the taste of wine.

Until now, quantitative studies have not examined how growing environment or grain variety affects the flavor of the final product in brewing and distillation. Rather, the same varieties of corn and wheat grown for food products and animal feed are often used for fermentation. Barley, though often grown as specific malting varieties for the base of most beers, is frequently malted in massive batches sourced from several different locations, effectively eliminating any effects of terroir.

Over the following pages, we're going to look at the efforts of plant breeders, maltsters, brewers, and distillers to discover whether the varieties and growing environments of grains affect the flavors of the drinks many of us love to drink: teetotalers beware.

Barley, Barley, Barley

Barley is thought to have been domesticated around the same time as wheat, 10,000 years ago (Badr et al., 2000). Almost as soon as it was cultivated, people began soaking the grain to encourage germination. They then dried and roasted germinated grains, creating toasty, malted, flavorful dishes and drinks. Ancient Egyptians even had a festival dedicated to beer drinking—the Tekh Festival (or “Festival of Drunkeness”).

Though not quite a Tekh Festival, as he tells it, about 12 years ago Pat Hayes and his colleagues were sitting around a table in a haunt in St. Paul, MN sipping cold beers. “We just wondered how barley was contributing to the flavor of beer,” Hayes says, “and we were all very innocent of the sensory analysis process involved.”

Hayes, a professor in the Department of Crop and Soil Science at Oregon State University (OSU) and an ASA and CSSA member, is uniquely suited for the challenge: he has been breeding barley for more than 30 years. To get things going, Hayes formed the Flavor Pack: a loose federation of craft brewers united by their common interest in beer flavor. As their research has progressed, they've received funding from the Brewers Association to continue their work.

Together, the team began an exploration of how it could breed barley strains better suited for malting and brewing. For us to understand exactly how the malting process and the malt qualities of barley play into beer flavor, it helps to know how beer is brewed. There are five major milestones: malting, making mash, fermentation, boiling, and bottling.

Malted, Mashed, Boiled, Fermented

If the base of your beer is barley, malting the grain is key.

First, a maltster cleans and dries the grains. Water is then added to the grain to increase moisture content before removing the water and letting it “air rest” (Lewis & Young, 2002). This process is often repeated two or three times until the grain is cast out in a thin layer and allowed to germinate.

Germinating the barley causes the slight breakdown of the endosperm cell walls, making fermentable sugars easily accessible for yeast. Brewers prefer barley for a beer base because it has a high ratio of starch to protein, giving the yeast plenty of sugar to digest and produce alcohol and carbon dioxide (MacLeod, 2004).

The maltster then takes germinated barley and “kilns” it to remove moisture, halt the germination process, and make enzymes available that give beer its distinctive flavor. Kilning the barley at too high of a temperature or for too long can cause the enzymes that break down starches into sugar during later stages of brewing to denature, preventing yeast from digesting those sugars.

A low temperature or short kiln makes for lightly roasted barley, resulting in light beers. Darker beers often take their colors and heavier, nuttier flavors from more intense kilning.

By now, you have malted barley, and the process moves into the hands of a brewer. The malt is ground up and soaked in hot water until the enzymes activate, breaking sugar down into fermentable forms. The mash is boiled, forming a sticky sweet liquid called “wort,” filled with sugars and flavor from the malted barley, forming the base for fermentation.

At this point, the brewer can add hops to taste, balancing the sweet wort with their bitter flavor. The brewer then adds yeast, which digests sugars in the wort and creates alcohol as a by-product as the beer is aged for a week or two, depending on the brewer's preference and the style of beer.

The brewer bottles or kegs the flat, uncarbonated beer, adding a small amount of sugar. One last round of fermentation in the bottle creates additional CO2, leaving consumers with the bubbly, distinctive flavor of a fresh beer.

Given this background information, it's clear that barley, the base of the whole beverage, could be a contributor to unique flavor.

Barley Crossing and Nano-Brewing

Pat Hayes and his team, including his then-graduate student, Dustin Herb, took the initiative to test both barley variety and growing environment as factors influencing flavor. Their study, published in the Journal of the American Society of Brewing Chemists, used genetic markers in experimental barleys and check varieties to correlate sensory descriptors in finished beers with both the barley variety and the location of its growth (Herb et al., 2017).

The team crossed OSU's popular strain of semi-dwarf barley, Full Pint (which is known for its unique flavor when brewed), with a second barley strain, Golden Promise, to create 200 doubled haploid selections.

“Since the 1960s, Golden Promise has been left behind in the race to breed for malting quality,” Hayes says. “Modern grain has much lower beta-glucan than Golden Promise while Golden Promise has less fermentable sugar. All these factors change the way it malts.”

The researchers selected the 34 most promising doubled haploids from this larger “Oregon Promise” group. The “Oregon Promise” subset was then grown in three distinct environments in Oregon: Corvallis, Lebanon, and Madras. Both parent grains are semi-dwarf, two-row barleys that were grown alongside the test varieties as controls.

The biggest issue the team ran into was producing enough grain to get adequate malt for brewing multiple samples. “Our efficiency for malting is about 80%,” Hayes says. “For micro-malting, we can sometimes work with as little as a single head of barley, which is around 10 grams of grain.”

Barley grain was sent to the USDA Cereal Crop Research Unit for micro-malting, and then two sample beers were brewed for each location/variety combination—one by Rahr Malting Co. and one by New Glarus Brewing Company. The beer output for each plot of grain was, in sum, two 500-mL bottles.

The nano-beers were 5% alcohol by volume and had hops added to the equivalent of 12 international bitterness units, or IBUs—about the same bitterness as a standard American lager. The tiny batches of beer needed only a quarter pound of malted barley from each variety to yield about a pint glass full of beer.

Sensory and Genetic Analysis

During sensory analysis, each nano-beer sample was blind taste-tested by a panel of trained analysts and compared with Miller High Life as a reference. The analysts rated beer on a set of standard flavors, like floral, grass, honey, toffee, sweet, roasted, or bitter. Based on these flavor profiles, the team ran ANOVAs to test whether genotype and environment had effects on the flavor outcomes of standardized beers.

Using quantitative trait locus (QTL) analysis, the team correlated notable flavors with specific regions in the genomes of each barley variety. They found 10 regions in the barley genome account for significant and heritable variations in sensory traits. Golden Promise contributed more to the “sweetness” of the beer while Full Pint tasted more “toasted.”

Some of the sensory descriptors evaluated by the panels were more pronounced in barley from certain environments, as well. Corvallis barley was significantly correlated to “cereal” flavors, compared with the same strains grown in other locations, while Madras grains showed off significantly higher honey, toasted, and toffee flavors.

Based on the pilot study, Hayes and Herb chose three Oregon Promise doubled haploids to grow in larger quantities, malted them at OSU's own malting facility, and then passed the malted barley to Deschutes Brewery for brewing. The resulting beers were assessed by expert sensory panels at cooperating craft breweries and by research and consumer panels at OSU. In addition, the beers were analyzed using metabolic profiling, building on Hayes's collaborations with other universities that are also studying the art and craft of beer and the plants that make it.

Notably, Harmonie Bettenhausen, a former brewer/cheesemaker and current Ph.D. candidate in the Department of Horticulture at Colorado State University, published a paper in Food Research International examining the way that malt source influences the flavor and chemistry of beer (Bettenhausen et al., 2018).

Like the team at OSU, Bettenhausen found an effect of malt variety on specific flavor compounds, both chemically and in a sensory analysis using trained panelists.

“We wanted to get at the heart of what [the beer] was all made up of and what was changing in it. What is the environmental influence on phenotype, and how is this all related to sensory attributes and flavor?” Bettenhausen says. “We're looking for classes of compounds that may be affecting the aromas of beer.”

Bettenhausen and her colleagues found that 16 out of 45 of the sensory traits analyzed could be accurately predicted at least 50% of the time using malt metabolite data. These findings, coupled with the genomic research the team completed, add another link in the chain indicating that the specific genetic makeup of a barley variety influences beer flavor in a heritable way.

In short, both Herb et al. (2017) and Bettenhausen et al. (2018) provide a solid foundation for exploring specific barley varieties and flavor. Another paper by Bettenhausen integrating malting, brewing, sensory, and metabolomics data is now in press in the Journal of the American Society of Brewing Chemists.

Crafting the Perfect Malt

Though the research on barley and flavor shows promise, there is still massive room for experimentation when it comes to testing the range of flavors malted barley can provide for beer.

Craft maltster and co-owner of a Madras farm called Mecca Grade Estate Malt, Seth Klann discussed his niche as a distinctive player in the craft beer game. Along with his father, Brad, Klann pitched the idea of setting up a production-grade floor-malt-style malting machine on his family farm after he came home and dabbled in home brewing.

“I got home from school and I started farming here,” Klann says. “At the same time, I started all-grain brewing in my garage…it wasn't enough to be brewing, I needed to be malting, too.”

Klann began floor-malting in the confines of his garage after a deep dive into the limited literature about malting at home. Many homebrewers use malt extract, the sticky, syrupy-sweet intermediate brewing product: the wort. Malt extract is the wort, concentrated, and ready for homebrewers to add yeast and begin fermenting. All-grain brewers take malted barley and create wort on their own, but Klann wanted to malt his own, family-farm grown grain, too.

“Floor malt is pretty intensive—you have to turn it every six hours. I had to figure it out: is there any way to mechanize this process? We came up with this giant machine with a series of conveyor belts,” Klann says.

The machine acts like M.C. Escher's “impossible staircase.” It moves germinated barley around a series of conveyor belts, heated to the proper temperature for each stage of germination and drying, and maintains a uniform grain depth of no more than 16 inches when fully germinated.

“Some maltsters, their grains beds are at least 3-ft deep, and when you go into kiln, sometimes they have static beds up to 8-ft deep,” Klann says. “You blow hot air through it, and you end up with different products throughout that stratification that all get blended together.”

Instead, Klann cites his floor malt method as a means of creating uniform malts without flavor variations or stratification from layers of uneven heating. Now Mecca Grade has two proprietary malt machines, producing more than 12 tons of finished malt every eight days.

The logical next step for the father-son farmer-artisan duo was to corner their own signature barley variety. A former OSU student, Klann partnered with Hayes's barley lab to find a cross of Full Pint they liked enough to grow on the farm.

“We have our own unique climate in Madras. We have our own unique malting process,” Klann says. “We knew we had this unique flavor, using Full Pint, but how far could we push it?”

Hayes had more than one hundred doubled haploids on hand, all with Full Pint as a parent. These were tested over a three-year period and finally whittled down to three top contenders based on agronomic performance and malting quality. These three selections are currently undergoing the same battery of sensory and metabolomic tests as the Oregon Promise selections. Eventually, Mecca Grade Estate will select one to grow on its farm exclusively, creating a niche, one-of-a-kind malt.

“Terroir is a thing,” Klann says. “We're using it and celebrating it…we have a cool story, we have a family farm, but it takes more than just a cool story. We want to make malt that has some appreciable flavor impact—that makes a craft beer good enough for people to go back and have a second pint.” Using their own Full Pint cross could be an ideal way for them to create a product no one else can replicate.

The Flavor of a Region

Mecca Grade Estate Malt is a great example of a small business that has embraced the niche role of craft maltsters and their importance to breweries and the impact that one (often overlooked) crop can have on innovative farmers.

According to the Brewers Association, beer sales account for $114.2 billion in the United States, annually, with craft beer cornering $27.6 billion at 7% annual sales growth—there are more than 7,000 microbreweries, regional breweries, and brewpubs producing their own unique beers (https://bit.ly/2LYtEok). All this to say that craft brewing is on the rise—from 2017 to 2018, the number of craft breweries in the United States increased 13.2%, according to the same Brewers Association research.

A market like this one heralds nothing but good news for breeders of grains used for brewing. Beer drinkers—particularly of the craft variety—are constantly on the lookout for new flavor profiles and the best-tasting brew. In a kind of “pie-in-the-sky” sort of world, as Seth Klann puts it, “Ideally, I'd like to see regional malthouses where…the regional flavor is imparted from that. It becomes the flavor of that place.”

Another researcher, Stephen Jones, has similar ideas about the impact of strong relationships between people in a region. Jones, the Director of The Bread Lab of Washington State University, Clif Bar & King Arthur Flour Endowed Chair in Organic Grain Breeding and Innovation, and member of ASA and CSSA, advocates for “revitalizing our local grain economies.”

The Bread Lab is a 10-year old project, located in Skagit Valley (north of Seattle, WA), in a maritime climate—far different from the dry-summer climate of Madras, OR. The Bread Lab focuses on ways to increase the impact of the plant breeders and researchers, focusing on “replicable, not scalable” models of impact for their findings.

“We work to make wheat, barley, rye, buckwheat, and other small grains more approachable and accessible,” Jones says. “If our producers are producing a grain here, it's not shipped off somewhere, it's malted here. It's distilled here, and it can be consumed here. Each time I say, ‘here,’ we're adding value to that crop. That's replicable.”

The Bread Lab cooperates with local brewers, bakers, distillers, farmers, and maltsters to find crop varieties that taste good and work well for everyone, but especially for farmers.

“We're confident that if we make our crops work for the farmer, first, then all the other arms of the system will figure it out,” Jones says. “We haven't been burned on that one yet. If your job is to create, then you can just do it. Our maltsters, they can malt anything. I think they could malt sawdust, if they had to. When a crop works well for the farmer, and if the yield is there, and you're working with craftspeople and artists, let them be craftspeople and artists.”

This goal of fostering both new and flavorful varieties of barley and fruitful relationships among plant breeders, farmers, maltsters, and craft brewers has had a noticeable impact on Skagit Valley itself. Jones mentions that more than 200 living-wage jobs have been created within a five-minute walk of the lab in the last three years—a functional example of the good that can come from cooperation at all levels of a grain product's production.

Breeding Corn for Better Whiskey

Incidentally, another grain has been the focus of studies on the relationship among growing environment, crop variety, and flavor. At Texas A&M University, Seth Murray has been looking at the way corn varieties and growing environments impact whiskey flavor, along with his Ph.D. distance student, Rob Arnold.

Murray is a professor and Butler Chair at Texas A&M, as well as Chair of the Agronomic Science Foundation, CSSA Fellow, and current Editor of The Plant Phenome Journal. Arnold is the Master Distiller at Firestone & Robertson Distilling Co.—the makers of TX Whiskey and TX Bourbon—in Fort Worth, TX.

Like beer, whiskey is made using a mash of grain that is fermented into beer; but instead of stopping there, the beer is put into a still and heated slowly so that the alcohol vapors evaporate, condense, and are captured. The result is an unaged liquor that distillers refer to as new-make whiskey.

If produced in the United States from a recipe of at least 51% corn and matured in new, charred oak barrels (along with some other, more technical rules), then the style of whiskey created is called bourbon, according to U.S. Federal Regulations governing distilled spirits (https://bit.ly/2M9gPHw).

Murray, Arnold, and the rest of their team have been looking at terroir and its effects on new-make bourbon whiskey. A recent PLOS One paper outlining Arnold's findings highlight the differences in flavors found by sensory panels evaluating the diluted new-make bourbon (Arnold et al., 2019).

The team grew three different yellow dent corn varieties in three different Texas locations, with one variety grown in an additional Texas environment. Their goal was to emphasize the diversity of growing environments in Texas and understand the way that varying soil types and agronomic techniques affect corn growth and distillation.

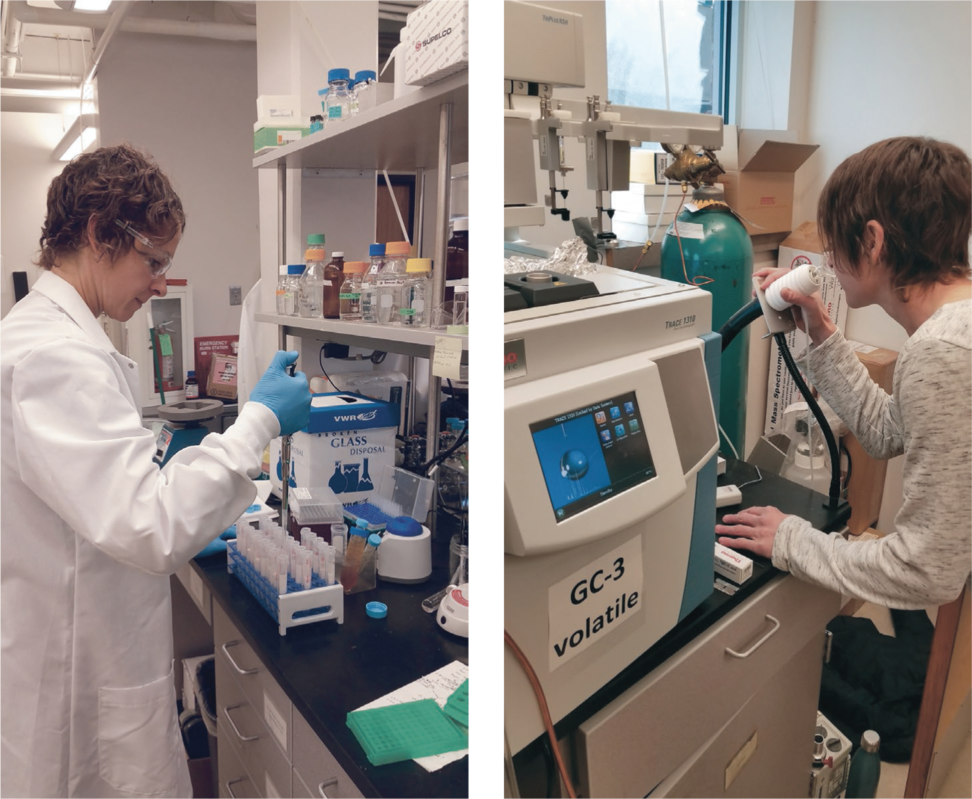

The researchers replicated milling, mashing, fermentation, and distillation methods used to make new-make whiskey at a lab scale but needed some help with chemical analysis.

Arnold teamed up with Texas A&M student Ale Ochoa, who was pursuing a master's degree in food chemistry. Ochoa utilized gas chromatography-mass spectrometry to detect and quantify the flavor compounds in the new-make whiskey samples. She further trained a sensory panel, much like the one used in the previously mentioned beer studies, to detect and quantify the different flavors in each sample.

They detected 30 important flavor compounds through chemical analysis and more than 10 flavors through sensory analysis that were meaningfully impacted by the corn variety, the terroir, or the interaction of the two.

With scientific support that corn variety and terroir do impact the flavor of whiskey, Arnold is now interested in exploring varieties that harbor unique flavors as compared with the commodity yellow dent corn that dominates the market.

“The modern varieties of yellow dent corn are used to make most of the bourbon in the United States,” Arnold explains. “These varieties were bred and selected for one purpose: yield. Most of this corn is harvested, then used to feed chickens or cows, or to make fuel ethanol. The science shows that as crops are bred for yield without any consideration for flavor, then less flavorful varieties are usually the result. This has already been studied in tomatoes…but anyone who has explored the flavors of heirloom tomatoes, carrots, potatoes, or grains will know that their flavors are usually superior to their modern counterparts.”

Arnold, a third-generation member of the bourbon industry, was in the middle of a biochemistry Ph.D. at the University of Texas Southwestern Medical Center when he started brewing beer in grad school. Arnold left his Ph.D. when Leonard Firestone and Troy Robertson offered him a job as their head distiller back in 2011. “I was their first employee, and I've been making whiskey ever since,” Arnold says.

In the process, Arnold began his distance Ph.D. at Texas A&M after talking with Murray. Arnold, along with Ochoa, who was actually hired by Firestone & Robertson after she graduated, screened dozens of promising hybrid varieties from Murray's program. They narrowed it down to three standouts using sensory analysis and lab-scale mashes and fermentations. By 2022, they hope nearly all of the corn used to make whiskey at Firestone & Robertson will be one of these varieties, removing their use of any commodity yellow dent corn varieties.

One of the biggest challenges for distillers starting out with a new grain is time. Unlike beer, whiskey requires a few years to age and mature into what would be found as a consumer product—some new-make and lightly aged whiskeys end up on liquor store shelves but most have been aged for at least four years.

As Murray puts it, “It makes it really hard if you've got to age bourbon for three to five years, and you don't know how it's going to taste, and you've got to commit to thousands of gallons of it…that can be a little risky. It also makes it hard to do science.”

To circle back to the team's PLOS One findings, benzaldehyde concentration in the corn itself was strongly correlated to a number of important flavor compounds in whiskey, including isoamyl acetate, non-anal, styrene, and ethyl-octanoate.

With this interesting link to quality, using benzaldehyde concentrations as an indicator before undergoing the time-consuming and expensive process of turning corn into whiskey could help the researchers find the best possible varieties to distill and age, mitigating a bit of the risk.

Whiskey as Leverage

Like craft brewing, craft distilling is a growing market. According to the Craft Spirits Data Project completed by the American Craft Spirits Association, the number of active craft distillers in the United States increased 15.5% in 2018 (https://bit.ly/2PYlnBQ). Growth is projected to continue, and the value of craft spirit retail sales in 2017 was $3.7 billion—a 30.1% increase in value compared with 2016 sales.

Leveraging beverages that many people enjoy (passionately) to better advocate for plant breeding and scientific research is a clever strategy to keep an important field of research in policymakers’ minds.

In conjunction with the Science Policy Office of ASA, CSSA, and SSSA, Seth Murray was able to take the team's new-make whiskey to Capitol Hill in Washington, DC and give policymakers and staffers a taste. The event, held last year in April, was one of the office's best attended. Murray spoke about the process of breeding plants for better whiskey, and let the staffers try standard, yellow-dent corn whiskey and the spirit made with their own specialty corn variety.

“People were fascinated,” says Karl Anderson, the Director of Government Relations for the Science Policy Office. “No one ever thought that science could be used to make a better tasting whiskey. They thought it was black magic, the way whiskey is made.”

Anderson, as a representative of the Societies, advocates for federal research funding, with particular focus on the Department of Agriculture, the National Science Foundation, and the Department of Energy. Holding events on Capitol Hill to keep staffers engaged and interested in these areas helps increase their focus on allocating funding to areas that will benefit members of the Societies. He says making research relevant to the average consumer—your Capitol Hill staffer, for example—helps keep scientific discovery as a whole fresh and interesting.

“You really can't go wrong talking about the value of agricultural research and then having people taste the difference between corn that was bred for yield and corn that was bred for flavor,” Murray says. “Show and taste.”

To bring things full circle, this emphasis on flavor in conjunction with plant breeding is just in its infancy. Projects involving further testing, scaling up batches, or trying out even more novel varieties may be the next step for artisans and plant breeders alike.

The complex network of relationships necessary to bring you a pint of craft beer also contributes to its unique value. As farmers, maltsters, brewers, distillers, and scientists begin collaborations focusing on flavor as an inherent property, brought to its full potential by certain unique environments, the possibility that flavor becomes regionalized and distinct is quickly becoming a reality.

The additional benefit of increased awareness of the innovation and care involved in plant breeding may also be a clever way to bring the importance of plant breeding to the public's attention.

As Anderson points out, meeting people where they are is the best way to foster connections and increase their interest in agricultural research goals. “If we want people to care about what we do,” Anderson says, “then we've got to think about what they value and how our research fits into that value proposition. Even if whiskey isn't going to feed the world, this kind of research still brings attention to science and the marvels of discovery.”

Of course, it might be a while before barley regions make a notable appearance alongside wines, but it does not seem so far-fetched to imagine that distinct flavors of Texas whiskey might be touted alongside Scotch or Irish, not for their style, but for the grains used within. And if encouraging people to think about the way plants can tickle their palates through a glass of craft beer with dinner or a sip (or three) of whiskey to wind down the night, then we're on the right track.

Arnold, R. J., Ochoa, A., Kerth, C. R., Miller, C. R., & Murray, S. C. (2019). Assessing the impact of corn variety and Texas terroir on flavor and alcohol yield in new-make bourbon whiskey. PLOS ONE14(8), e-0220787. https://doi.org/10.1371/journal.pone.0220787

Badr, A., Müller, K., Schäfer-Pregl, R., El Rabey, H., Effgen, S., Ibrahim, H. H., Pozzi, C., Rohde, W., & Salamini, F. (2000). On the origin and domestication history of barley (Hordeum vulgare). Molecular Biology and Evolution, 17(4), 499-510. https://doi.org/10.1093/oxfordjournals.molbev.a026330

Herb, D., Filichkin, T., Fisk, S., Helgerson, L., & Hayes, P. (2017). Effects of barley (Hordeum vulgare L.) variety and growing environment on beer flavor. Journal of the American Society of Brewing Chemists, 75(4), 345-353. https://doi.org/10.1094/ASBCJ-2017-4860-01

MacLeod, L. (2004). BARLEY | Malting. In C. Wrigley (Ed.), Encyclopedia of grain science (pp. 68-76). Elsevier.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.