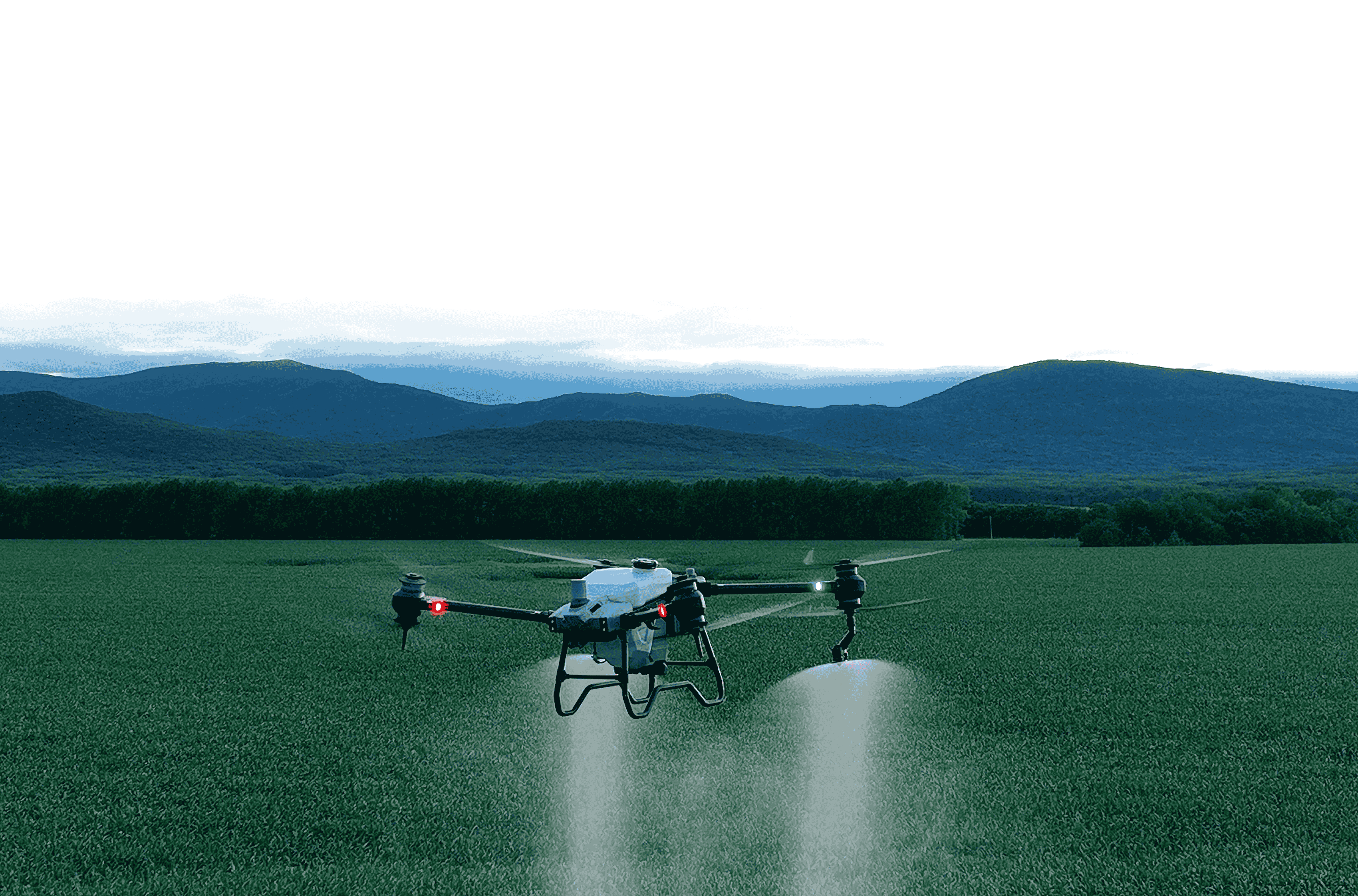

Ag Application Drones Are Gaining Ground in Canada, But Obstacles Remain

Ag drones don’t currently replace ground sprayers, but they can serve as an additional tool. There are many thousands of acres where drones fit right now in Canada, and even though we’re still perfecting our knowledge about drone application and awaiting regulatory clearance, drones are a good answer to many growers’ needs. Earn 1.5 CEUs in Crop Management by reading this article and taking the quiz at https://web.sciencesocieties.org/Learning-Center/Courses.

Farmers in Canada are currently using ag application drones to spread cover crop seeds, fertilizers, organics such as fulvic and humic acid, and micronutrients such as boron, zinc, and manganese.

Many are enthusiastic to exploit the up‐and‐coming technology of drone application of pesticides and herbicides, but the national Pesticide Management Regulatory Agency (PMRA), under Health Canada, requires more data about product efficacy and safety of the technology for the environment and human health before it may approve these uses.

“We need to make sure that [drone] introduction into our space is done properly,” says Tom Wolf, scientist in ag spray technology at Agrimetrix Research & Training in Saskatoon, SK, “so that we have consumer confidence, regulatory confidence, and ultimately, we prevent problems. The regulatory agency needs to do a risk assessment as part of its due diligence. It has to know, what’s the risk to water bodies? What’s the risk to terrestrial environments? What’s the risk to birds, vertebrates, invertebrates?”

In Canada, as in the United States, the pesticide label is the law, so before any registered crop chemical could be legally applied by drone, that use must appear on the label.

“Drones are phenomenal tools for a few things,” says Mark Ledebuhr, whose Michigan‐based company, Application Insight, designs and evaluates pesticide applications. These are some areas where drones have immediate potential once the regulatory hurdles are cleared:

- spot treatment of weeds, pests, or nutrient deficiencies. “If you’re only spraying 5–10% of the field, that’s a win—for the environment, for the farmer, for weed control,” Ledebuhr says.

- low‐acreage, high‐value crops. One example: Spotted wing drosophila is a problem in blueberries, cherries, and other soft fruit. Fighting it requires a low‐volume spray sometimes every five to seven days during harvest. Another example: application of insect pheromones for mating disruption, in which a chemical is applied about every meter along the row in an orchard or vineyard.

- Difficult‐to‐reach places—for example, vineyards and Christmas tree plantations on steep slopes where it’s difficult for ground‐based equipment to go—and areas dangerous for crewed aerial applicators, such as near tree lines and power lines.

- post‐emergence contact sprays on tight crops such as canola or fungicide application at corn tasseling.

U.S. Ag Drone Regulations

The USEPA has deferred to the states to regulate application of pesticides using drones. Most states allow spray applications under the aerial label for most products. Ag drone aerial applicators in the U.S. must be licensed by the Federal Aviation Administration and register their drones. Some states have additional requirements for ag drone spraying.

The Basics of Drone Application

To begin, the operator sets the bounds for the flight by flying or walking the boundaries or importing a shapefile from a geographic information system (GIS). They also specify parameters such as the flight height and speed, application volume, and water rate. Drones can fly to centimeter‐level accuracy and adjust automatically for topography.

The operator chooses the nozzle size, which affects droplet size. “The smaller droplet size usually has higher efficacy,” says Markus Weber, president of LandView Drones in Edmonton, AB. “But the big trade‐off is the larger the droplet, the less you have drift. So it’s the trade‐off between efficacy and drift that you really need to manage carefully.” Operators typically use a smaller droplet when more coverage is required and a coarse droplet for products such as a systemic herbicide or downwind of a stream or organic field.

The Regulatory Scenario in Canada

PMRA Regulates Spray

In Canada, PMRA administers the Pest Control Products Act, under which pesticides and herbicides are registered and regulated. The only legal ag application of these chemicals by drones in Canada is currently done for research.

“To protect the public good, the safety of our water, our air, our soil, our population, we have to generate the required data,” Wolf says, before we allow drone application of crop chemicals.

Academics and commercial service providers like him are conducting research to help provide the answers that PMRA requires to move forward with regulations. Research trials focus on determining the spray swath width of different drone models, efficacy, chemical residue, and long‐term effects.

“I expect that it will still take several years before we see widespread use of drones in agriculture in Canada,” says Markus Weber. “Our regulatory bodies are careful. We pride ourselves on our food safety, and I expect that will continue to be the case.”

“Until we get more studies, unfortunately, I kind of see both sides,” says Adrian Rivard, president of Drone Spray Canada in Blenheim, ON. His company contracts with government agencies and chemical manufacturers to conduct research authorization testing with ag drones. “I understand that we do need more studies,” he says. “But I’m also a service provider, so I’d love to be able to get our business kicked up into high gear and more people working for us.”

Regulatory approvals will likely include specific terms and conditions for chemical use, including a range of wind speeds and setback from water.

There’s another impediment to the uptake of ag drones in Canada: regulations on the aircraft themselves.

Transport Canada Regulates Drones

Transport Canada Civil Aviation regulates aircraft in Canada, including drones greater than 250 g (0.55 lb), which must be registered with the agency. All operators of these aircraft must pass a test to obtain a pilot certificate for basic operations. Almost everyone flying an ag drone—one that is heavier than 25 kg (55 lb) loaded weight, beyond visual line‐of‐sight, and/or carrying hazardous payloads—also needs a Special Flight Operations Certificate.

Cory Southam, of Strongfield Environmental Solutions, Inc., in Lacombe, AB, and Bryan Sanders, of HSE‐UAV, Casselberry, FL, fly an XAG V40 drone with rotary atomizer during a spray demonstration. Photo courtesy of RPAAS Spray Drone Workshop and HSE‐UAV.com.

The requirements are the same no matter the purpose of the flight, but the licensing process is currently being simplified for ag drones because the risk is generally lower given the distance from population centers and airports.

In 2022 the DJI Agras T10, one of the lightest spray drones available in Canada at 13 kg (28 lb), was most popular with Markus Weber’s customers in Alberta. Because it’s under 25 kg fully loaded, it requires only a basic operations certificate.

Advantages

Lack of Crop Damage

A big advantage for growers is the ability to make applications without damaging a standing crop, reducing yield, or compacting soil. Drone application allows “timely applications even if it recently rained 2 inches,” Rivard says. It doesn’t spread fungal spores or invasive weed seeds and can help address the farm labor shortage. It gives an accurate GPS record of application data, and operating costs are low.

Saves Money and Chemicals

Another advantage is the ability to save money on chemicals and increase their efficacy by applying only when and where needed. For example, says Felix Weber, president of Ag Business and Crop, Inc., in Palmerston, ON, a grower could apply a chemical only to the areas of a field that are flowering and come back in two days to spray the areas that are flowering then without having to drive through the crop twice.

Growers could apply crop chemicals only to the perhaps 5–20% of the field that actually has a problem, thereby saving significant money, time, and environmental impact. “The decision making is quite different,” Markus Weber says. “Currently you have to decide whether you want to apply a very expensive product over an entire field. The new decision point becomes, do I want to apply this expensive product to the worst 10% of my field?”

Operator Safety

Another class of advantages is operator safety. “The safety gains for pilots are huge,” versus crewed aerial application, says Ramon Leon, professor of weed biology and ecology at North Carolina State University. Reduced exposure to spray chemicals is another aspect of operator safety. “I would argue that [drone application] has a much lower risk of human exposure,” says Markus Weber, “because often these small drones are being used to replace a backpack sprayer.” There is some concern about chemical exposure during drone filling, which happens frequently because of the small tank size, but drone designers are moving toward closed or automated filling systems to cut down on this risk.

Limitations

Besides the main limitation in Canada of the lack of regulatory‐approved ag chemicals for drone application, and despite the dramatic progress in drone capability since their introduction around 2015, the technology still has some limitations that make it most suited for certain niches so far.

Cost and Efficiency

Markus Weber reports that interest in purchasing ag drones leapt in spring 2022 although numbers sold remain low. “For a farm here in Alberta or Saskatchewan that’s anywhere less than 5,000 acres,” he says, “drones would look appealing as their primary application tool if it was allowed.”

“The interest comes from people who have done the math,” Wolf explains. For a 2,023‐ha (5,000‐ac) farm, you’ll need one ground sprayer with probably a 37‐m (120‐ft) boom. It can cover 40–61 ha/hour (100–150 ac/hour) and costs about Can$750,000 (US$557,000). You could buy a large drone with a swath of 6–8 m (20–25 ft), including batteries and charger, for about Can$40,000 (US$29,700). You’d need six of those drones to have the 120‐ft boom width. But that totals only Can$240,000 (US$178,400). So the capital investment is relatively low in comparison.

Ag drones have low efficiency in uniform applications. Some large models can spray 12–15 ha/hour (30–37 ac/hour), much less than conventional ground sprayers. Commercial operators such as Rivard increase efficiency by “swarming” drones—in which one operator commands up to five drones at once on one controller. Swarming requires another person to refill the drones and tend the battery charger and generator.

Battery Life

With a fully loaded tank, a fully charged battery powers 10–15 minutes of flight time. A fast charger takes about 15 minutes for a quick charge, which typically comes from a 15‐horsepower gas generator by the field. Most ag drone packages include three or four batteries.

Payload Capacity

Another important limitation is the payload capacity. The popular DJI Agras T10 drone has an 8 L tank (2 U.S. gal) that allows it to remain under the Transport Canada 25‐kg loaded weight limit. This necessitates a low application volume. The 5‐m (16‐ft) spray swath width allows coverage of about 0.4 ha (1 ac) before reloading.

The weight restriction is less of a problem for application of cover crop seed and other lightweight materials.

Coverage

As the payload capacity increases, so generally does the effective spray swath width. The DJI Agras T40, one of the largest commercially available drones in Canada, can cover 21 ha (52 ac) per flight hour and has a spray tank of 40 L (10.5 gal) and a swath width of 11 m (36 ft). But the 90‐kg (198 lb) loaded weight requires a Special Flight Operations Certificate.

Sufficient percent coverage for drone‐applied pesticides typically ranges from 5 to 30%, varies with the chemical and the circumstances, and is influenced by the spray volume and the type of nozzle used.

Many drone operators want to apply at aerial label rates or even lower rates approaching 5–10 L/ha to maintain high productivity, but Ledebuhr cautions that spraying with a drone doesn’t change the basic physics of a good spray application. Very low application rates come with high risk of failed application. It’s possible that weed or insect resistance issues could arise if coverage is too light to kill the target organism.

Many ag drone application experts say that the downwash from copters creates more turbulence than fixed‐wing drones, which moves plant leaves up and down, giving better coverage of the canopy than with a ground sprayer. However, Wolf says he’s still waiting for the data on this question.

Drift and Drone Configuration Variability

Probably the greatest data gap, says Dan Martin, research engineer with USDA‐ARS in Texas, is the need for more drift studies conducted under various conditions with drones of different configurations. Helicopter‐like drones have two, four, six, or eight rotors. Some have nozzles under the rotors; some are on a boom. We need to know which configurations give the widest effective spray swath, how uniform the spray pattern is, and how well the spray controls its target.

“On an ag chemical label,” says Ledebuhr, “oftentimes regulators and registrants want to assume that machinery is not a variable, but it is. We know that type of drone and how a drone is used can significantly impact the application, for better or worse.”

An October 2022 ag drone conference in British Columbia showed that more researchers are entering this field, and the data gaps are being filled, giving regulators more data on which to base their decisions.

Wolf, who is known on social media as “Nozzle_Guy,” is excited about a new drone that has a twin rotor with a rotary atomizer. With the flick of a switch in flight, the nozzle can spin at different speeds, which produces different sized droplets. This technology could be used to produce smaller droplets in a field’s interior and coarser droplets near the field edge.

Pump Capacity and Clogging

The drone pump is limited in the amount of liquid it can deliver simultaneously to more than one nozzle, so operators may not be able to apply at the rate they’d like to. They can get around this by slowing the flight speed, but that reduces productivity. Many newer drone models have more than one pump.

It can be difficult to dissolve dry chemical in the small drone tank for the application rate of 8–11 L/ha (2–3 gal/ac), and the extremely concentrated solution can cause the pump to clog. This can make the application rate less than the operator intends. Some ag chemical companies are considering whether they need different, more soluble formulations for drone application.

Filling in the Data Gaps: Current Research

Currently there is little governmental financial support for ag spray drone research in Canada. The registrants—the companies that want to register their products for drone application—are footing the bill. Wolf notes, however, that under the United States, Mexico, Canada Agreement—the new version of NAFTA—there is “harmonization of regulations,” meaning that PMRA staff communicate with USEPA staff, so they don’t replicate data.

Increasing Scientific Rigor of Testing

There’s a need for more scientifically rigorous research into drone‐related questions, starting with more replications to increase confidence in the final result, Martin says.

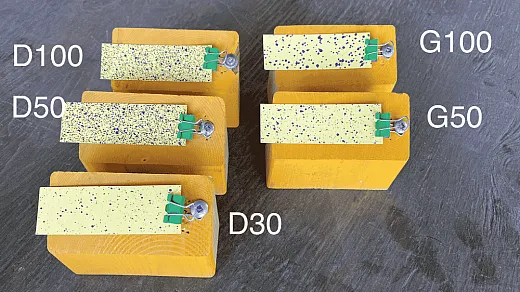

There’s also a need for more complete data from swath width and uniformity testing. Ledebuhr, who describes himself as a drone evangelist, has developed an inexpensive and rapid method that sprays food‐grade dye on calculator roll paper attached with rubber bands to reusable PVC trim board set up perpendicular to the flight path.

This method is fast and inexpensive enough to do a swath test for each application, which he recommends because the swath width can vary even hour to hour with the weather or any change in the way the drone is used. It also allows analysis of the swath all the way across the swath width, not just at every meter, as more conventional methods do.

To further improve on this method, Ledebuhr’s engineering team at Application Insight invented a machine they call the Swath Gobbler that analyzes the percent coverage and hits per area on the paper roll down to 50 microns, half the width of a human hair. The Swath Gobbler collects and analyzes data in the field quickly enough that adjustments can be made to get the coverage rate needed. This technique may be put to work in standardizing testing.

“A lot of what we’re hearing from manufacturers is optimistic,” Ledebuhr says. Spray application may not be uniform over the swath, and the swath is often a different width than the applicator thinks. There’s a wide variety of drones today and a wide variety in operator skill, which both make a difference.

International Collaboration to Address Issues and Move Regulation Forward

In 2021 the Organization for Economic Co‐operation and Development (OECD), which represents 38 industrialized countries in North and South America, Europe, and the Asia/Pacific region, and the European Commission, released a report on the global state of knowledge on the use of drones for agricultural application of crop chemicals. The report concluded that drone applications may “create significantly different risks from those associated with more traditional and established methods of application” (p. 11) and stated that new assessments were likely to be needed to encourage more widespread adoption of the technology. The report also identified an urgent need for standard testing protocols for ag drones as well as standards for calibration, deployment, efficacy testing, operator exposure, and spray drift assessment to ease regulatory approval.

The Unmanned Aerial Pesticide Application System Task Force, a U.S.‐based international industry coalition, sprang from the OECD report’s recommendations on research and data needs. The task force is pooling financial and other resources to sponsor research that helps answer the questions that remain about ag drone spraying so that the regulatory process can go forward for safe application internationally. The task force seeks to:

- assess off‐site exposure

- support OECD efforts to classify drones into groups to generalize testing

- survey drone manufacturers about future trends in design to simplify drone group testing

- develop a best‐practices guide that addresses pitfalls, troubleshooting, and preliminary operation parameters with the hope of improving and standardizing spray system pumps, nozzle placement, and closed‐tank loading systems

- develop standard methods to support regulation internationally

The task force sees drone‐based crop chemical application as an important part of the progression toward precision agriculture that will increase its sustainability.

Conclusion

Ag drones don’t currently replace ground sprayers, but they can serve as an additional tool. There are many thousands of acres where drones fit right now in Canada, and even though we’re still perfecting our knowledge about drone application and awaiting regulatory clearance, drones are a good answer to many growers’ needs.

Self-Study CEU Quiz

Earn 1.5 CEUs in Crop Management by taking the quiz for the article at https://web.sciencesocieties.org/Learning-Center/Courses. For your convenience, the quiz is printed below. The CEU can be purchased individually, or you can access as part of your Online Classroom Subscription.

- The USEPA regulates application of pesticides using drones in the U.S.

- True.

- False.

- Ag drone aerial applicators in the U.S. must be licensed by

- the Federal Aviation Administration.

- the USEPA.

- the states in which they operate.

- All of the above.

- How accurate are today’s drones?

- They can fly to meter‐level accuracy.

- They can fly to centimeter‐level accuracy.

- They can fly to millimeter‐level accuracy.

- They can fly to nanometer‐level accuracy.

- When applying pesticides, a smaller droplet size leads to higher efficacy but also higher drift.

- True.

- False.

- Due to regulatory concerns, according to an expert cited in this story, when will ag drone usage in Canada become common?

- In 2023.

- Within several years.

- Within a decade.

- It is unlikely Canadian regulatory authorities will permit widespread use of ag drones in the foreseeable future.

- In Canada, which drone operators do NOT require a Special Flight Operations Certificate?

- Operators using a drone carrying hazardous payloads.

- Operators using a drone heavier than 25 kg (55 lb) loaded weight.

- Operators using a drone beyond visual line‐of‐sight.

- None of the above.

- Ag drones offer many advantages. Which of the following is NOT cited as an advantage in the article?

- Higher yields.

- Safer for humans.

- Cost savings from reduced use of farm workers, machinery, and fertilizer.

- Better for the environment.

- Ag drones would be useful for farmers who want to target specific areas of a field at specific times with specific amounts of pesticide, rather than treat an entire field at one fell swoop.

- True.

- False.

- Using drones also comes with some disadvantages. Which of the following is NOT cited as a limitation in the article?

- Battery life.

- Limited payload capacity.

- Expensive training.

- Clogged pumps.

- For farms under 5,000 acres (2,023 ha), how would the capital investment for conventional equipment compare with drones, according to an expert cited in the article?

- Conventional would be about 10% more expensive.

- Conventional would be about 25% more expensive.

- Conventional would be twice as expensive.

- Conventional would be more than three times as expensive.

- What is meant by “swarming drones”?

- A group of up to five drones controlled by one operator simultaneously.

- Drones that malfunction.

- A dozen or more drones deployed concurrently.

- Drones whose motors are calibrated to emit a specific frequency.

- The type of drone and how it is used can significantly impact the application.

- True.

- False.

- An international industry coalition is investigating some of the open questions about ag drone use. Which of the following is NOT among the areas mentioned as being addressed by the group?

- Assessing off‐site exposure to chemicals applied by drones.

- Developing drone use regulations to apply to all nations.

- Developing best‐practices guide to improve and standardize spray system pumps, nozzle placement, and other drone components.

- Surveying drone manufacturers about design trends.

- Some researchers are experimenting with ways to measure the swath width of sprayed areas as they work toward standardized testing of drones. One researcher devised a low‐cost technique out of several everyday items. Which of the following items is NOT used in this technique?

- Rubber bands.

- Paper clips.

- Food dye.

- Calculator paper.

- In what area is drone research most needed, according to the article?

- Drift.

- Battery life.

- Drone design.

- Swath width.

Text © . The authors. CC BY-NC-ND 4.0. Except where otherwise noted, images are subject to copyright. Any reuse without express permission from the copyright owner is prohibited.